Exploring the Versatility of Polycarbonate Tubes: Innovations in Design and Application

In recent years, the demand for polycarbonate tubes has surged, driven by their unique properties and versatility across various industries. According to a report by ResearchAndMarkets, the global polycarbonate market is expected to reach USD 20.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.3% from 2020 to 2025. This remarkable growth can be attributed to the outstanding strength, lightweight nature, and excellent optical clarity of polycarbonate materials, making them ideal for applications in sectors such as construction, automotive, and consumer goods. Innovations in design have further expanded the potential uses of polycarbonate tubes, enabling customized solutions that meet specific industry needs. As we explore the versatility of polycarbonate tubes in this article, we will delve into the latest advancements and applications, demonstrating how this remarkable material continues to shape modern design and functionality.

The Unique Properties of Polycarbonate Tubes and Their Advantages

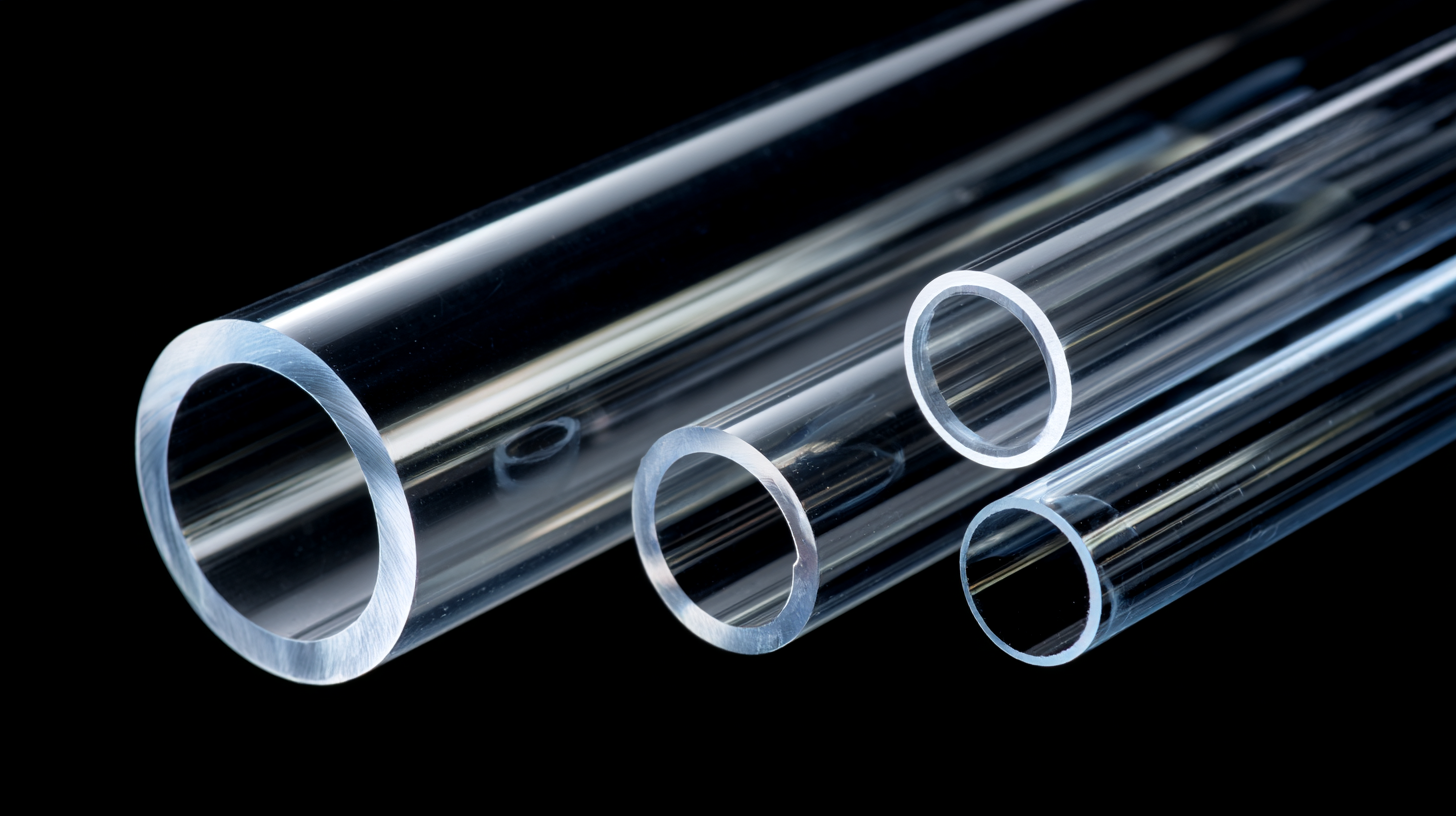

Polycarbonate tubes have emerged as a key material in various industries due to their unique properties such as high impact resistance, excellent durability, and remarkable optical clarity. These tubes can withstand extreme temperatures and harsh weather conditions, making them ideal for applications ranging from construction to medical devices. According to a recent market report, the global polycarbonate market is expected to reach a value of approximately $23 billion by 2026, driven by the increasing demand for lightweight and versatile materials.

One of the major advantages of polycarbonate tubes is their ability to be easily molded and shaped, allowing for innovative designs that meet specific requirements. With the rise of advanced manufacturing techniques, including 3D printing, designers can experiment with complex geometries that were previously difficult to achieve. This versatility not only enhances the aesthetic appeal of products but also improves their functionality. As noted in a recent filament guide, various materials can be combined with polycarbonate to enhance its properties, further expanding its application range.

Tips: When selecting polycarbonate tubes for your projects, consider factors such as thickness and diameter to ensure suitable performance. Additionally, pairing polycarbonate with other filaments during 3D printing can yield functional prototypes that reduce production costs and lead times. Always test the material's compatibility with your design software for optimal results.

Exploring the Versatility of Polycarbonate Tubes: Innovations in Design and Application

| Property | Description | Advantages | Applications |

|---|---|---|---|

| Impact Resistance | Polycarbonate is known for its high impact resistance, making it virtually unbreakable. | Increased safety and durability compared to glass and acrylic. | Safety glasses, riot shields, and protective equipment. |

| UV Resistance | Polycarbonate can be treated for enhanced UV resistance, minimizing degradation from sunlight. | Long-lasting clarity and protection from harmful UV rays. | Greenhouses, outdoor signage, and windows. |

| Thermal Insulation | Polycarbonate offers excellent thermal insulation properties. | Energy-saving and temperature control in buildings. | Skylights, roofing systems, and insulation panels. |

| Lightweight | Polycarbonate is significantly lighter than glass, reducing the overall weight of structures. | Easier handling and installation, lower transportation costs. | Automotive parts, portable displays, and protective barriers. |

| Chemical Resistance | Polycarbonate is resistant to many acids and bases, enhancing its usability in various environments. | Longevity and safety in chemical-processing applications. | Laboratory equipment, chemical storage containers, and medical devices. |

Innovative Design Trends for Polycarbonate Tubes in Various Industries

Polycarbonate tubes are experiencing a remarkable evolution, becoming increasingly vital across various industries due to their unique properties and innovative design trends. One notable trend is the integration of polycarbonate tubes into architectural applications, providing not only structural support but also enhanced aesthetic appeal. Their lightweight nature, combined with excellent impact resistance and transparency, allows designers to create spaces that blend safety and style, a feature highlighted at the recent International Builders' Show. These tubes are transforming traditional design concepts, leading to a surge in their use in modern construction projects.

In addition to construction, polycarbonate tubes are making waves in the realm of industrial equipment and product development. Incubators for new businesses, like those emerging in Detroit, are harnessing the versatility of polycarbonate tubes to develop innovative products that meet contemporary demands. Their adaptability through customization fosters creativity, allowing industries to push boundaries and explore new applications. As trends evolve, the ongoing exploration of polycarbonate tubes will undoubtedly lead to fresh innovations, driving advancements in design and functionality across sectors.

Applications of Polycarbonate Tubes: From Industrial to Creative Uses

Polycarbonate tubes have gained significant attention in various sectors due to their remarkable properties, making them a versatile choice for both industrial and creative applications. In the medical field, the strength, clarity, and toughness of polycarbonate make it an ideal material for devices such as housings for surgical instruments and components of diagnostic equipment. These tubes can withstand high-impact forces, ensuring the safety and longevity of medical devices while providing a clear view of internal mechanics during usage.

Beyond medical applications, polycarbonate tubes have also carved a niche in creative industries. Designers and artists utilize these tubes in innovative ways, from creating striking lighting fixtures to crafting unique furniture pieces. Their ability to be molded and shaped easily allows for intricate designs that enhance aesthetic appeal while maintaining functional integrity. As the design landscape continues to evolve, the adaptability of polycarbonate tubes will likely lead to even more imaginative uses, demonstrating their potential to bridge the gap between practicality and creativity.

Sustainability and Environmental Impact of Polycarbonate Tubes

The sustainability of polycarbonate tubes has become a focal point in discussions about modern materials. Unlike traditional plastics, polycarbonate is engineered to be durable and lightweight, allowing for reduced material usage without compromising strength. This characteristic not only minimizes the environmental footprint during production but also extends the functional lifespan of the product, leading to less frequent replacement and waste. Furthermore, polycarbonate's recyclability presents an opportunity for a more circular economy, where materials can be repurposed rather than discarded.

Environmental impact extends beyond the lifecycle of the material itself. Innovations in the design of polycarbonate tubes have led to the development of applications that replace less eco-friendly options, such as glass and metal. These tubes are increasingly used in various sectors, including construction, automotive, and consumer goods, thereby promoting sustainable practices. As companies shift towards materials that align with environmental goals, polycarbonate tubes offer a compelling solution, combining efficiency with ecological responsibility.

Exploring the Versatility of Polycarbonate Tubes: Innovations in Design and Application

Future Innovations and Trends in Polycarbonate Tube Technology

The future of polycarbonate tube technology is poised for groundbreaking innovations, driven by advancements in manufacturing processes and a growing demand across various industries. As per a recent industry report by Grand View Research, the global polycarbonate market is expected to reach USD 22.82 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.1%. This surge is largely attributed to the material's lightweight, high-impact resistance, and versatility, making it suitable for applications in automotive, electronics, and construction. Researchers are exploring new formulations and processing techniques to enhance the thermal stability and UV resistance of polycarbonate tubes, paving the way for their use in more demanding environments.

**Tip:** When considering polycarbonate tubes for your projects, look for products with enhanced UV stability and impact resistance, especially if they will be used outdoors or in high-traffic areas.

Furthermore, trends indicate an increasing shift toward sustainable materials. Companies are investigating bio-based polycarbonate options that maintain the same desirable properties while reducing environmental impact. Collaborations between manufacturers and universities are fostering innovations that could lead to lighter, stronger, and more eco-friendly polycarbonate solutions.

**Tip:** Stay updated on the latest material innovations by subscribing to industry newsletters and attending relevant trade shows, as they can provide insights into emerging technologies and potential suppliers.

Related Posts

-

How to Choose the Best Polycarbonate Tube for Your DIY Projects and Home Improvements

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions

-

Exploring the Benefits of Plastic Hinges: Durability and Cost-Efficiency in Modern Applications

-

Exploring the Benefits of Plastic Channels in Modern Infrastructure Development

-

Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production

-

Unlocking the Benefits of PVDF Tubing: Why It’s the Future of Industrial Solutions