Top Trends in Rigid Plastic Tubing for 2025 What You Need to Know

In the ever-evolving landscape of the rigid plastic tubing industry, significant trends are anticipated to shape the market in 2025. As the demand for lightweight yet durable materials continues to soar across various sectors, experts like Dr. Emily Johnson, a leading authority in polymer science, emphasize the importance of innovation in rigid plastic tubing technologies. "The future of rigid plastic tubing lies not only in enhancing the functionality but also in increasing sustainability and efficiency throughout the supply chain," she remarked during a recent industry conference.

These anticipated trends reflect a broader movement towards eco-friendly practices and the use of advanced materials that offer improved performance characteristics. With the integration of smarter manufacturing processes and a growing emphasis on recyclability, companies are poised to meet the challenges and opportunities that lie ahead. In this article, we will explore the key developments and insights that define the future of rigid plastic tubing, ensuring stakeholders are well-prepared for the changes that 2025 will bring.

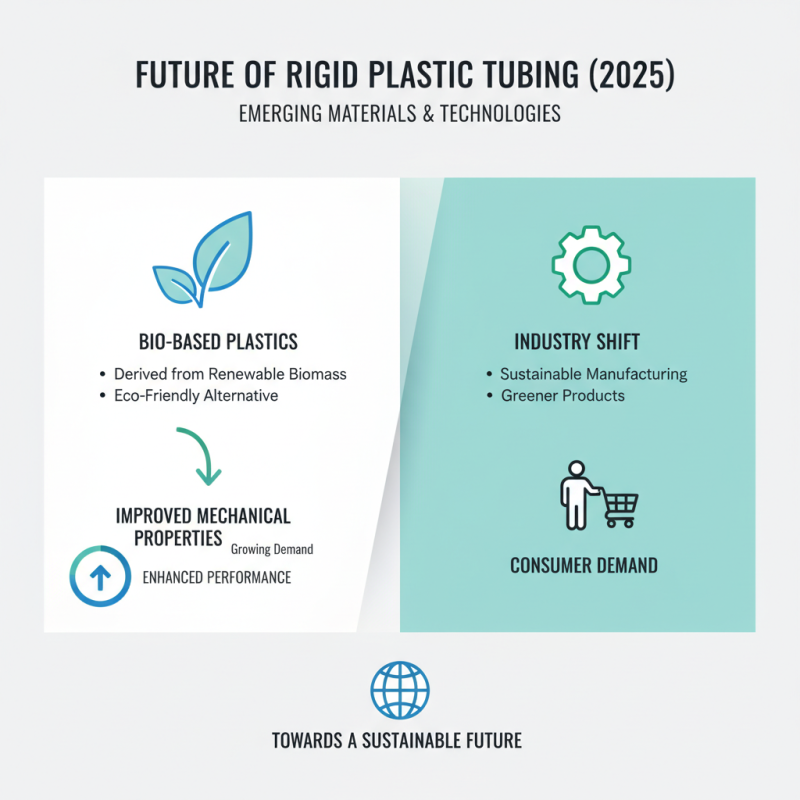

Emerging Materials and Technologies in Rigid Plastic Tubing by 2025

As the demand for rigid plastic tubing continues to grow, the industry is poised to adopt several emerging materials and technologies by 2025. One of the most notable trends is the increasing utilization of bio-based plastics. These materials, derived from renewable biomass sources, not only provide an eco-friendly alternative to traditional fossil fuel-based plastics but also offer improved mechanical properties that enhance the performance of tubing applications. This shift will likely encourage more sustainable manufacturing practices and respond to consumer demand for greener products.

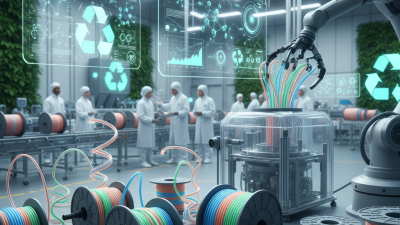

In tandem with advancements in materials, innovations in production technologies are set to redefine the rigid plastic tubing landscape. Techniques such as 3D printing and advanced extrusion processes are gaining traction, enabling manufacturers to create complex geometries and customized solutions with greater efficiency. These technologies allow for lower waste generation and faster prototyping, making it easier for companies to adapt to changing market needs. As these trends evolve, the combination of innovative materials and cutting-edge production methods is expected to significantly enhance the functionality and sustainability of rigid plastic tubing.

Projected Market Growth and Demand for Rigid Plastic Tubing

The rigid plastic tubing market is projected to experience significant growth in the coming years, driven by increased demand across various industries, including healthcare, construction, and packaging. As manufacturers seek to enhance product performance and versatility, the shift toward sustainable materials will further accelerate market expansion. By 2025, rigid plastic tubing is expected to become a critical component in efficient fluid management systems and specialized applications, emphasizing the need for innovation and adaptability in design.

Tips for manufacturers aiming to capitalize on this trend include investing in research and development to explore advanced resin formulations that improve durability and reduce environmental impact. Additionally, establishing strong supply chain partnerships can help ensure access to high-quality raw materials. Businesses should also consider customer feedback to refine their products and align with market demands, as user-centric design can significantly influence competitiveness in this evolving landscape.

Moreover, keeping an eye on regulatory trends can guide manufacturers in compliance while unlocking new market opportunities. As the focus on sustainability grows, developing eco-friendly tubing solutions will not only meet emerging regulations but can also appeal to environmentally conscious consumers. Embracing these strategies will be essential for thriving in the projected robust market for rigid plastic tubing by 2025.

Top Trends in Rigid Plastic Tubing for 2025

| Trend | Projected Growth Rate (%) | Key Drivers | Applications |

|---|---|---|---|

| Sustainability | 15% | Increased regulations on plastic waste | Medical, Food Packaging |

| Geographic Expansion | 10% | Emerging markets demand | Automotive, Electronics |

| Advanced Manufacturing Techniques | 12% | Adoption of 3D printing and automation | Custom Applications, Prototyping |

| Smart Tubing | 20% | Integration of IoT and sensors | Healthcare Monitoring, Industrial Applications |

| Customization and Flexibility | 18% | Rising demand for tailored solutions | Consumer Products, Industrial Uses |

Sustainability Trends: Recycled and Biodegradable Options in Tubing

As sustainability becomes increasingly vital in manufacturing, the rigid plastic tubing industry is witnessing a significant shift towards recycled and biodegradable options. According to a recent report by Smithers, the market for recycled plastics is expected to grow at a compound annual growth rate (CAGR) of 8.9% from 2020 to 2025, indicating a robust demand for sustainable materials. This surge is partly driven by escalating regulatory measures aimed at reducing plastic waste and encouraging circular economy practices.

Biodegradable materials are also gaining traction, offering manufacturers an alternative solution that aligns with environmental goals without compromising on performance. A study by the Ellen MacArthur Foundation indicates that bioplastics could hold a significant share of the plastics market, potentially reaching 30% by 2030. Innovations in biodegradable tubing, made from materials like polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are paving the way for eco-friendly applications in various sectors, ranging from medical to food packaging. These advancements not only reduce the environmental footprint but also cater to consumers' growing preference for sustainable options in their purchases.

Innovations in Manufacturing Processes for Enhanced Durability

As we look forward to 2025, the rigid plastic tubing industry is set to undergo significant transformations, particularly in the area of manufacturing processes. Enhanced durability is a key focus, as manufacturers adopt innovative techniques to improve the strength and longevity of their products. Advanced extrusion methods combined with new polymer blends are paving the way for tubing that can withstand extreme temperatures and pressures, making them suitable for a wider range of applications from pharmaceuticals to construction.

Tips for choosing the right rigid plastic tubing: Always consider the specific environmental conditions where the tubing will be used, such as temperature variations and exposure to chemicals. Testing for compatibility with the intended application can prevent future failures and ensure longevity. Additionally, look for manufacturers who prioritize sustainable practices in their production processes, as this can reflect on the quality and durability of the final product.

In the quest for enhanced performance, the integration of smart technologies into rigid plastic tubing production is becoming more prevalent. Automation and monitoring systems are being implemented to maintain consistent quality and to identify any potential defects early in the manufacturing process. This not only reduces waste but also ensures that the tubing meets stringent industry standards, thus increasing reliability and customer satisfaction.

Key Applications Driving the Rigid Plastic Tubing Market in 2025

The rigid plastic tubing market is anticipated to witness significant growth in 2025, driven by several key applications across various industries. One of the primary sectors propelling this demand is the medical industry, where rigid plastic tubing is extensively used for devices such as IV lines, catheters, and various surgical instruments. A report by MarketsandMarkets projects that the global medical tubing market, which includes rigid plastic options, will grow from USD 6.4 billion in 2020 to USD 10.9 billion by 2025, reflecting a compound annual growth rate (CAGR) of 11.1%. This growth can be attributed to an increasing prevalence of chronic diseases and a heightened focus on healthcare, particularly in the wake of the ongoing global health challenges.

In addition to healthcare, the demand for rigid plastic tubing in the automotive and construction sectors is on the rise. The automotive industry frequently utilizes these components for fuel lines, coolant tubes, and air intake systems due to their durability and resistance to various environmental factors. According to a research study from Mordor Intelligence, the automotive plastic tubing market is expected to reach USD 1.5 billion by 2025, driven by a growing trend towards lightweight materials and improved fuel efficiency. Furthermore, the construction industry increasingly relies on rigid plastic tubing for plumbing, wiring, and safety measures, as the benefits of lightweight, corrosion-resistant, and flexible materials become more evident.

Overall, the rigid plastic tubing market in 2025 will be driven by innovations in material technology and the ever-growing demand across these crucial sectors, indicating a robust landscape for manufacturers and suppliers alike.

Top Trends in Rigid Plastic Tubing for 2025

This bar chart illustrates the projected market demand for rigid plastic tubing across key applications in 2025. The medical sector is expected to lead in demand, followed by construction and automotive industries.

Related Posts

-

2025 Top Trends in Flexible Plastic Tubing: Innovations and Applications

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions

-

How to Choose the Best Flexible Plastic Tubing for Your Needs

-

Innovative Ways to Use Layflat Polythene Tubing in Your Next Project

-

10 Essential Tips for Optimizing Plastic Extrusion Profiles and Enhancing Production Efficiency

-

Understanding the Role of PVC Extrusions in Sustainable Building Designs