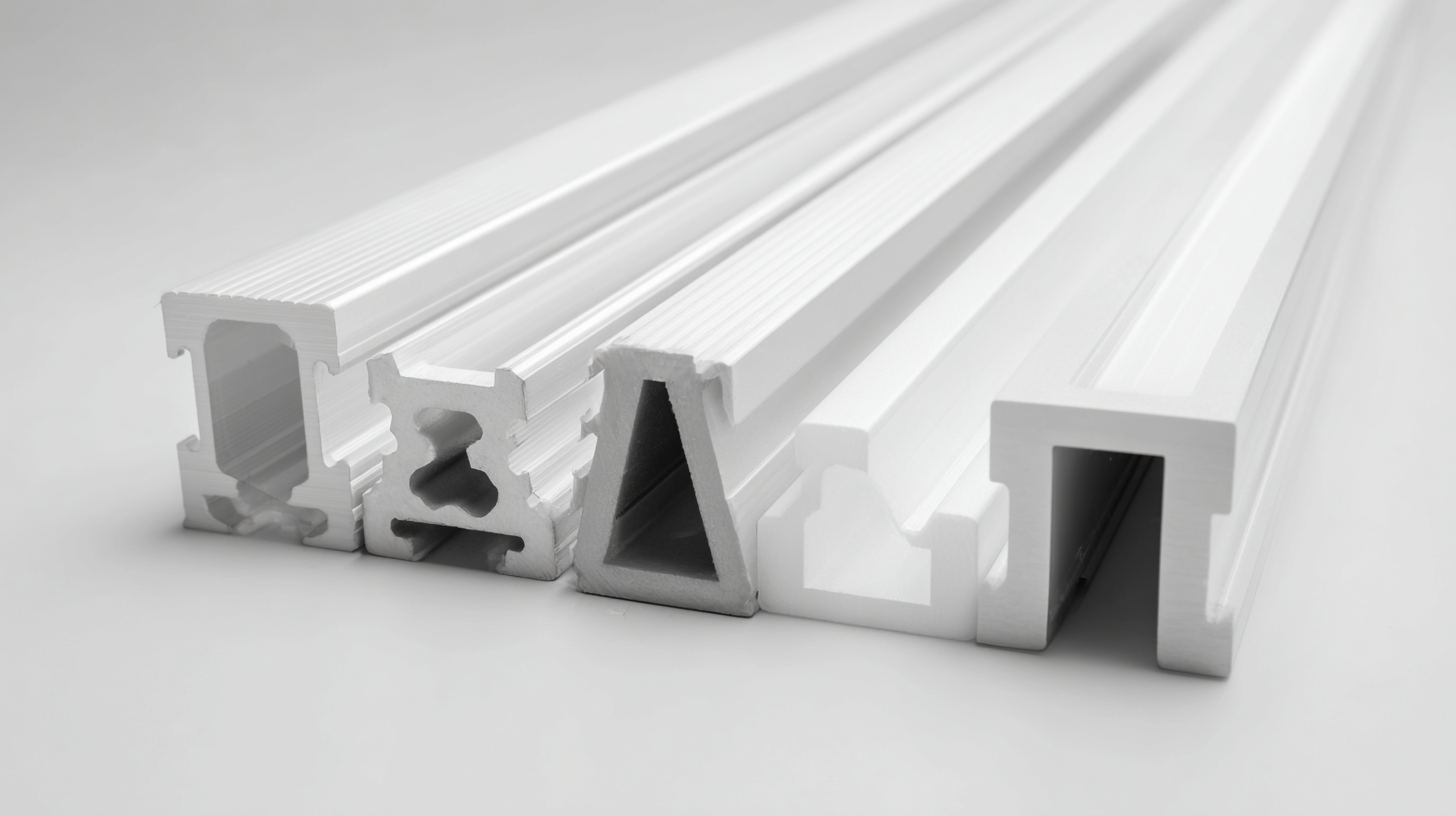

2025 Top 5 PVC Extrusion Profiles for Durable and Versatile Applications

In the realm of construction and manufacturing, the demand for durable and versatile materials has led to an increased interest in PVC extrusion profiles. These profiles, made from polyvinyl chloride, are known for their exceptional durability, resistance to weathering, and cost-effectiveness. According to a recent market analysis by Research and Markets, the global PVC extrusion market is projected to reach $25 billion by 2025, indicating a robust growth driven by the rising applications in various sectors such as building and construction, automotive, and electronics.

Industry expert Dr. Jane Smith, a leading figure in the PVC extrusion sector, emphasizes the significance of these profiles: "PVC extrusion profiles are not only integral to modern architecture but also play a crucial role in enhancing energy efficiency and sustainability in construction." This underscores the versatility of PVC extrusion profiles, which can be tailored to meet diverse needs, ranging from window frames and doors to plumbing and electrical conduits. As we explore the top 5 PVC extrusion profiles for 2025, it becomes evident that these innovative solutions are essential for industries looking to balance performance with sustainability.

The Growing Demand for PVC Extrusion Profiles in Construction and Infrastructure

The growing demand for PVC extrusion profiles in the construction and infrastructure sectors is reshaping industry standards. According to a recent market analysis report, the global PVC extrusion market is projected to reach USD 31.5 billion by 2025, driven largely by the ongoing urbanization and infrastructure development efforts worldwide. PVC profiles are favored for their durability, versatility, and cost-effectiveness, making them a prime choice for window frames, cladding, and conduit applications.

One of the significant advantages of PVC extrusion profiles is their ability to withstand harsh weather conditions and resist chemical exposure, which is critical in construction. A report by the Freedonia Group indicates that the demand for extruded PVC applications in non-residential construction is anticipated to grow at a compound annual growth rate (CAGR) of 5.6% through 2025. This growth trend suggests that more construction projects will leverage PVC materials for enhanced longevity and performance.

Tips: When considering PVC profiles for your next project, always check for certifications that guarantee quality and compliance with environmental standards. Additionally, explore diverse designs and finishes that can elevate the aesthetic appeal of your construction while maintaining durability. Emphasizing sustainability, choose manufacturers that utilize recycled materials in their production processes.

Key Properties of PVC Extrusion Profiles: Strength, Durability, and Versatility

PVC extrusion profiles are recognized for their exceptional strength, durability, and versatility, making them ideal for a wide range of applications. The intrinsic properties of PVC allow these profiles to withstand harsh environmental conditions, which is crucial in construction, automotive, and industrial settings. Their robust nature not only ensures long-lasting performance but also contributes to safety and reliability in various applications, appealing to manufacturers aiming for sustainability and efficiency.

Moreover, the advancements in polymer technology are enhancing the performance characteristics of PVC extrusion profiles. Innovations in material formulation enable higher impact strength and cold-temperature resilience, thereby broadening the scope of their use. Manufacturers are increasingly incorporating these high-performance polymers to address complex demands in industries like packaging and transportation. The versatility of PVC extrusion profiles continues to drive their adoption across sectors, reinforcing their position as a go-to solution for sustainable and durable design.

Innovative Applications of PVC Profiles in Energy-Efficient Building Solutions

The innovative applications of PVC profiles in energy-efficient building solutions are gaining traction as the construction industry increasingly prioritizes sustainability. PVC extrusion profiles offer excellent versatility and durability, making them ideal for various applications in energy-efficient buildings. These profiles can be utilized in window frames, door frames, and partition walls, significantly enhancing insulation properties, which in turn reduces energy consumption for heating and cooling purposes.

Moreover, the lightweight nature of PVC enables easier handling and installation, minimizing labor costs and time. As the global market for PVC is projected to grow significantly, reaching approximately $963.2 billion by 2031, the demand for energy-efficient building solutions will further drive innovations in PVC profile applications. The incorporation of PVC in building design not only supports environmental goals by promoting energy efficiency but also provides long-lasting, low-maintenance solutions for builders and homeowners alike.

Market Trends: The Rise of Eco-Friendly Materials in PVC Production

The increasing demand for eco-friendly materials in the PVC production industry is a significant market trend driving growth. As consumers and businesses alike become more environmentally conscious, the focus on sustainable practices and renewable energy sources has intensified. This shift towards greener alternatives is not only influenced by regulatory pressures but also by a growing awareness of the benefits of using recyclable materials, such as those derived from renewable resources.

The PVC stabilizer market, projected to grow significantly from 2024 to 2030, demonstrates how the industry is adapting to these trends. With an anticipated value increase from USD 5.60 Billion to USD 7.60 Billion, this sector is actively investing in the development of more sustainable products that align with the eco-friendly movement. Innovations in PVC applications, particularly in packaging and construction, are further supported by advancements in recyclable solutions. This creates a robust environment for growth as the industry embraces practices that not only enhance performance but also prioritize environmental responsibility.

2025 Top 5 PVC Extrusion Profiles for Durable and Versatile Applications

| Profile Type | Applications | Durability (Years) | Eco-Friendly Material Options | Market Growth (%) |

|---|---|---|---|---|

| Window Profiles | Residential and Commercial Windows | 25 | Recycled PVC, Bio-based Additives | 7.5 |

| Decking Profiles | Outdoor Decks and Patios | 30 | Wood-Plastic Composites | 6.3 |

| Fencing Profiles | Residential and Commercial Fences | 20 | Recycled PVC | 5.0 |

| Roofing Profiles | Commercial Roofing Applications | 35 | Bio-based Polymers | 8.8 |

| Profile for Pipes | Plumbing and Drainage | 40 | Eco-friendly PVC Compounds | 10.2 |

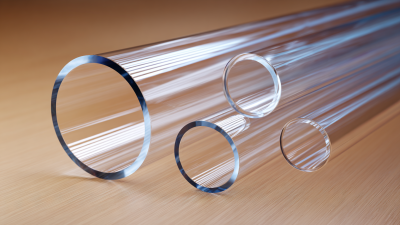

Future Prospects: Technological Advancements in PVC Extrusion Techniques

As the PVC extrusion industry progresses, technological advancements are playing a pivotal role in enhancing the versatility and durability of products. Innovations in extrusion techniques are allowing for the development of high-performance PVC profiles that cater to a range of applications, including construction, electrical, and plumbing sectors. Improved extrusion machinery and techniques, such as multi-layer co-extrusion and the incorporation of advanced additives, are facilitating the production of lighter, more resilient, and environmentally friendly PVC products.

The global PVC pipe market is witnessing substantial growth, driven by rising demand across various industries. This trend is evident in the expanding market for essential PVC pipe types, including Schedule 40, Schedule 80, and DWV pipes. Technological improvements in processing methods contribute significantly to this growth, enabling manufacturers to increase production efficiency while maintaining product quality. Furthermore, as industries strive for sustainability, advancements that enhance recyclability and reduce production waste are becoming crucial, ensuring that the PVC extrusion sector remains competitive in a rapidly evolving market landscape.

2025 Top 5 PVC Extrusion Profiles for Durable and Versatile Applications

Related Posts

-

Understanding the Role of PVC Extrusions in Sustainable Building Designs

-

How to Choose the Best Polycarbonate Tube for Your DIY Projects and Home Improvements

-

Exploring the Benefits of Plastic Channels in Modern Infrastructure Development

-

Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production

-

Innovative Techniques in Plastic Extrusion Transforming Manufacturing for the Future

-

Exploring the Benefits of Plastic Hinges: Durability and Cost-Efficiency in Modern Applications