Understanding the Role of PVC Extrusions in Sustainable Building Designs

In the quest for sustainable building practices, the role of PVC extrusions has emerged as a pivotal factor in enhancing energy efficiency and reducing environmental impact. According to the Vinyl Institute, approximately 71% of all PVC products are used in construction, demonstrating the material's essential contribution to sustainable development in the industry.

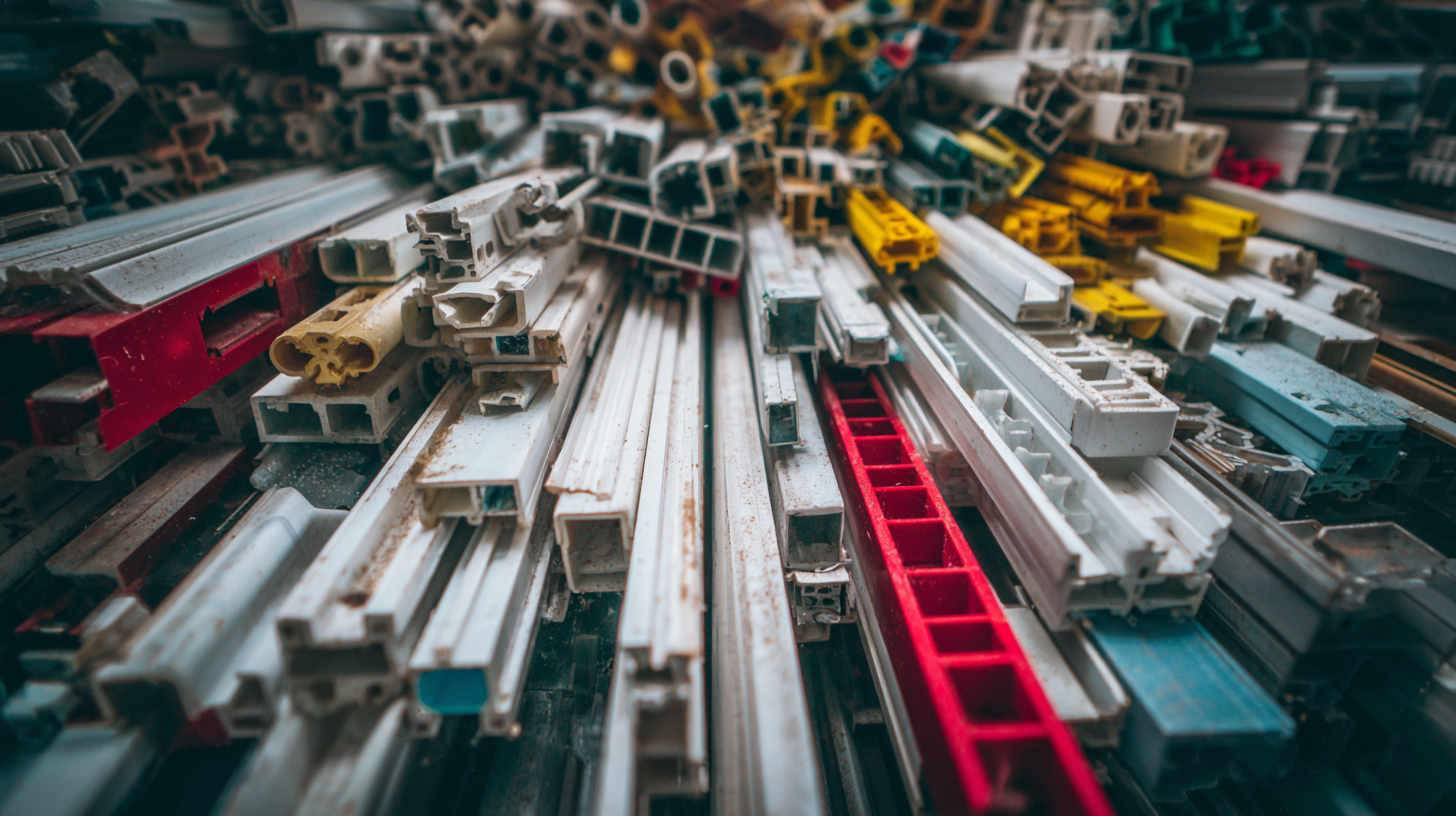

PVC extrusions, characterized by their versatility and durability, are increasingly being recognized for their ability to meet both aesthetic and performance standards in modern architectural designs.

PVC extrusions, characterized by their versatility and durability, are increasingly being recognized for their ability to meet both aesthetic and performance standards in modern architectural designs.

Moreover, a recent report from the Global PVC Market Analysis indicates that the demand for PVC in construction applications is expected to grow by 4.5% annually through 2025. This trend underscores the industry's commitment to harnessing materials like PVC extrusions, which offer sustainable attributes such as recyclability and low energy consumption during production. By integrating PVC extrusions into building designs, architects and builders can not only comply with rigorous energy efficiency codes but also contribute to a circular economy, thereby minimizing waste and fostering sustainability in the built environment.

The Environmental Benefits of PVC Extrusions in Construction

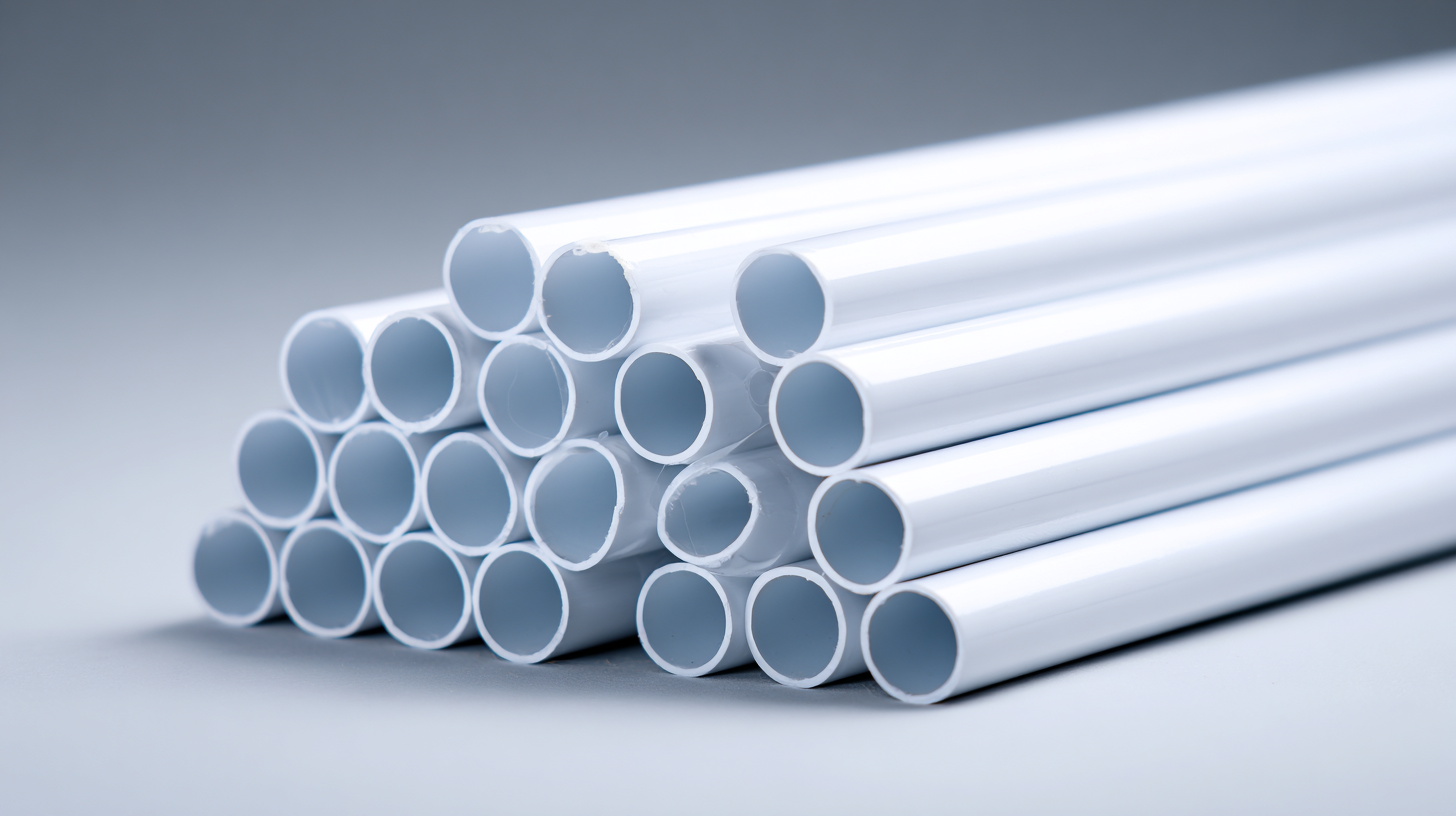

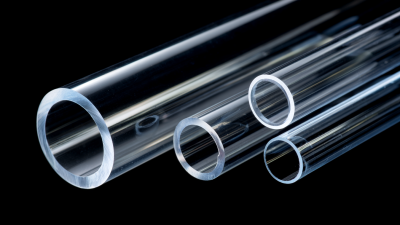

PVC extrusions are increasingly recognized for their environmental benefits in sustainable building designs. As a versatile material, PVC can be engineered into various shapes and sizes, providing substantial flexibility in construction. It is known for its durability and resistance to weathering, thereby reducing maintenance requirements and extending the lifespan of building components. This longevity not only minimizes resource consumption over time but also contributes to less waste in landfills.

According to market analysis, the demand for building materials that offer sustainability is on the rise, with forecasts suggesting that the market for aluminum extrusions will reach approximately $63.1 million by 2033, growing at a compound annual growth rate (CAGR) of 4.4%. This trend indicates a shifting focus towards materials that not only perform well but also align with green building standards. PVC extrusions possess the unique advantage of being recyclable, further enhancing their appeal within the realm of eco-friendly construction. As the industry moves toward more sustainable practices, PVC will likely play a crucial role in meeting environmental objectives while still fulfilling the performance needs of modern architecture.

Understanding the Role of PVC Extrusions in Sustainable Building Designs

This chart illustrates the environmental benefits of PVC extrusions in construction, highlighting key advantages such as recyclability, energy efficiency, waste reduction, durability, and cost-effectiveness. Each factor contributes significantly to sustainable building designs.

Innovative Applications of PVC Extrusions for Sustainable Materials

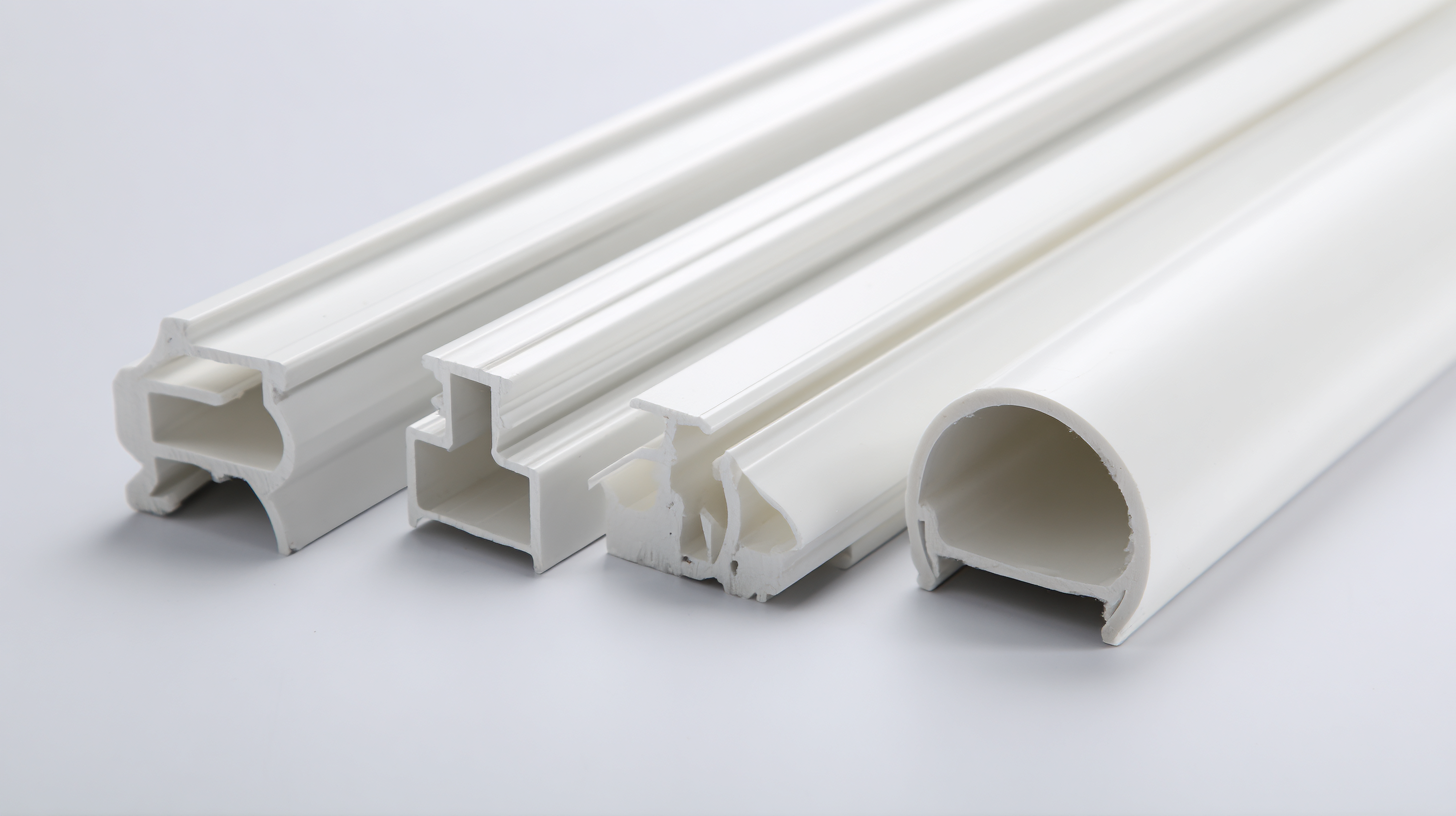

PVC extrusions play a crucial role in sustainable building designs, offering innovative applications that contribute to eco-friendly construction practices. With the global focus on reducing carbon footprints and increasing energy efficiency, the use of PVC as a sustainable material is gaining traction in various sectors. The versatility of PVC extrusions allows architects and builders to create not only functional components like window frames and siding but also aesthetic enhancements that align with modern sustainable design principles.

The market for sustainable materials, including PVC extrusions, is expected to grow significantly in the coming years. Reports indicate that the global polyolefin elastomers (POE) market, which includes sustainable material applications, is projected to reach $3.32 billion by 2033, growing at a compound annual growth rate (CAGR) of 3.46%. Additionally, the aluminum extrusion market is also seeing notable growth, with a forecasted value of $63.1 million by 2033 and a CAGR of 4.4%. These trends highlight the increasing demand for materials that not only meet functional requirements but also support sustainability initiatives in building design.

Energy Efficiency Enhancements through PVC Extrusion Design

PVC extrusions are becoming increasingly vital in sustainable building designs, particularly in enhancing energy efficiency. According to a report by the Vinyl Institute, buildings constructed with PVC materials can achieve up to 30% energy savings compared to traditional materials. This is primarily due to the thermal insulation properties of PVC extrusions, which minimize heat loss and reduce the energy required for heating and cooling systems.

Integrating PVC extrusions in window frames, doors, and insulation products allows for better sealing against drafts, further improving energy efficiency. The U.S. Department of Energy indicates that well-insulated homes can save homeowners between $200 to $500 annually on energy bills. Additionally, the versatility of PVC allows designers to create complex shapes and profiles that not only meet aesthetic demands but also optimize the performance of the building envelope.

**Tip:** When selecting PVC extrusion products, look for those with high R-values to ensure optimal insulation performance.

**Tip:** Consider utilizing double or triple-glazed windows in combination with PVC extrusions. This combination significantly enhances thermal performance, leading to more energy savings in the long run.

Understanding the Role of PVC Extrusions in Sustainable Building Designs

| Dimension | PVC Extrusion Type | Energy Efficiency Impact | Sustainability Benefits |

|---|---|---|---|

| Thermal Insulation | Vinyl Windows | Reduced heat transfer | Lower energy consumption |

| Water Resistance | PVC Cladding | Prevention of mold and mildew | Durability and low maintenance |

| Structural Strength | PVC Pipes | Longer lifespan and integrity | Resource efficiency |

| Energy Saving | Insulated Doors | Minimized HVAC load | Lower carbon footprint |

| Recyclability | PVC Extrusion Profiles | Contributes to circular economy | Reduced waste in landfills |

Durability and Lifespan: How PVC Extrusions Contribute to Sustainability

PVC extrusions play a crucial role in sustainable building designs, primarily due to their durability and long lifespan. As the construction industry grapples with the urgent need for environmentally friendly materials, PVC stands out because it is both lightweight and resilient, contributing to the overall performance and longevity of structures. The durability of PVC extrusions reduces the frequency of replacements and repairs, which in turn minimizes waste and resource consumption throughout a building's lifecycle.

Moreover, advancements in the recycling and upcycling of PVC contribute to its sustainability profile. Innovative strategies, such as the reprocessing of plastic waste into reusable materials, are gaining traction. These practices not only help to mitigate the impact of single-use plastics but also align with the principles of a circular economy. By integrating recycled PVC into building designs, developers can reduce their reliance on virgin materials, further supporting sustainability efforts in the construction sector.

As educational campaigns reveal the benefits of PVC in infrastructure improvement and environmental management, the material's role in fostering sustainable building practices continues to grow.

The Future of PVC Extrusions in Green Building Standards and Certifications

The future of PVC extrusions in green building standards and certifications is promising, as the construction industry increasingly prioritizes sustainability. According to a report from the Vinyl Institute, PVC is one of the most widely recycled plastics, with over 900 million pounds of PVC recycled in the U.S. each year. This positions PVC extrusions as an attractive option for builders seeking to comply with stringent green building certifications like LEED (Leadership in Energy and Environmental Design). As manufacturers adopt more advanced recycling technologies, the closed-loop recycling process of PVC ensures that energy consumption and waste are minimized, crucial components in achieving eco-friendly building status.

Moreover, the performance attributes of PVC extrusions align tightly with the criteria set by various green building programs. They offer excellent thermal insulation properties, contributing to reduced energy consumption in buildings. According to the Green Building Alliance, buildings that utilize PVC for cladding and framing can achieve up to 20% greater energy efficiency compared to those that do not. As the demand for sustainable materials grows, the integration of PVC extrusions into building designs not only meets changing market regulations but also reinforces a commitment to environmental stewardship, ultimately helping builders achieve their green building goals.

Related Posts

-

Innovative Ways to Use Layflat Polythene Tubing in Your Next Project

-

Innovative Techniques in Plastic Extrusion Transforming Manufacturing for the Future

-

Exploring the Benefits of Plastic Hinges: Durability and Cost-Efficiency in Modern Applications

-

Exploring the Versatility of Polycarbonate Tubes: Innovations in Design and Application

-

Exploring the Benefits of Plastic Channels in Modern Infrastructure Development

-

Unlocking the Benefits of PVDF Tubing: Why It’s the Future of Industrial Solutions