What is a Plastic Extruder and How Does it Work in Manufacturing Processes

Plastic extrusion is a crucial manufacturing process utilized in producing a wide range of plastic products, from simple sheets to complex profiles. According to a report by the Plastic Industry Association, the U.S. plastic industry is expected to reach a market value of over $650 billion by 2026, driven largely by advancements in extrusion technologies. At the heart of this transformation lies the plastic extruder, a machine designed to melt and shape plastic materials into continuous forms, thereby streamlining production and enhancing efficiency.

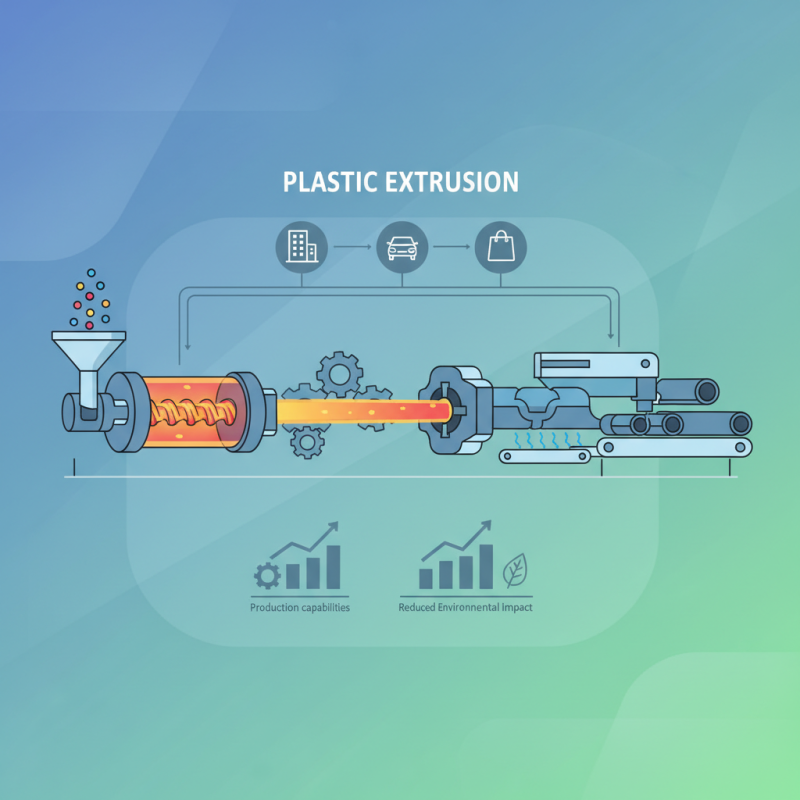

Understanding how a plastic extruder works is essential for manufacturers aiming to optimize their production lines. The extrusion process begins with plastic pellets being fed into a heated barrel, where they are melted and mixed thoroughly. This process not only ensures uniformity in the material but also facilitates the ability to create intricate designs and profiles that are vital in various applications, including construction, automotive, and consumer goods. The growing demand for innovative and sustainable plastic products underscores the importance of mastering the intricacies of the plastic extruder, making it a key player in the manufacturing landscape. Reports indicate that the extrusion sector is continuously evolving, with more companies investing in state-of-the-art extruders to improve production capabilities and reduce environmental impact.

What Is a Plastic Extruder? An Overview of Its Definition and Purpose

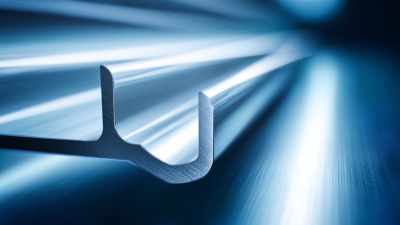

A plastic extruder is a vital machine used in the manufacturing industry to process plastic materials into various shapes and forms. This equipment works by heating plastic granules until they reach a molten state and then forcing this liquid plastic through a specially designed die. The shape of the die determines the final profile of the extruded product, which can range from simple sheets to complex tubing or custom profiles. The process is continuous, allowing for large-scale production while maintaining precise control over dimensions and material properties.

The primary purpose of a plastic extruder is to transform raw plastic materials into usable forms that can be further manufactured into end products. This transformation enables manufacturers to create a wide array of products, including pipes, films, and automotive parts. The extruder's design also allows for the incorporation of additives and colorants during the melting process, ensuring that the finished products meet specific performance requirements and aesthetic preferences. As a result, plastic extruders play a crucial role in enhancing efficiency and versatility in plastic manufacturing processes.

What is a Plastic Extruder and How Does it Work in Manufacturing Processes

| Dimension | Description |

|---|---|

| Definition | A machine that transforms raw plastic into a continuous profile. |

| Process Type | Thermoplastic extrusion. |

| Key Components | Hopper, barrel, screw, die, and cooling system. |

| Applications | Pipes, sheets, films, and profiles manufacturing. |

| Advantages | High efficiency, consistency in production, and ability to produce complex shapes. |

| Material Compatibility | Compatible with various thermoplastics such as PVC, PP, and PET. |

| Challenges | Material degradation, setup time, and equipment maintenance. |

The Components of a Plastic Extruder: Key Parts and Their Functions

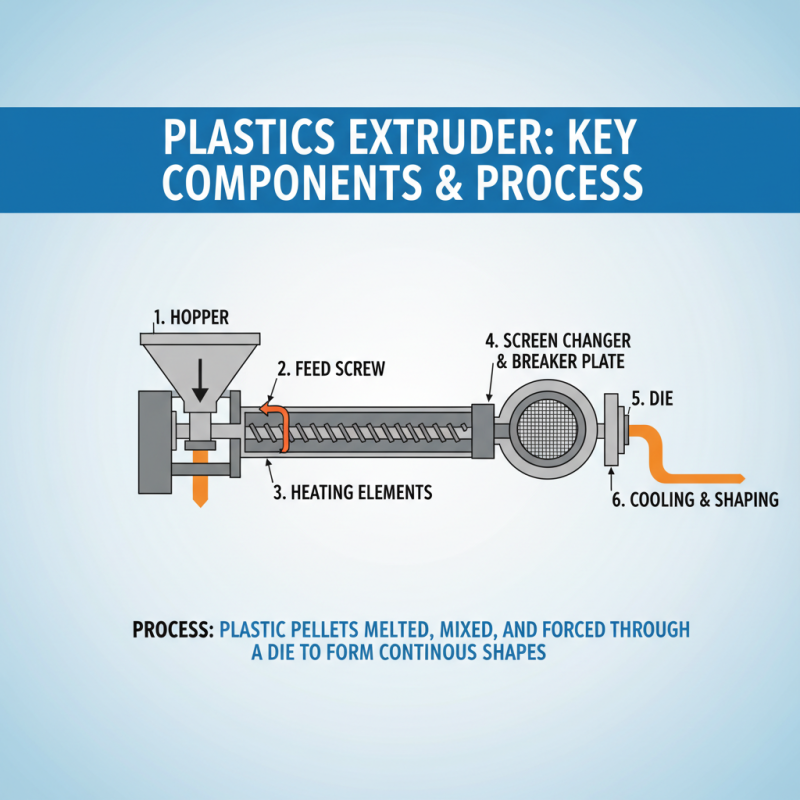

A plastic extruder is a sophisticated machine critical to various manufacturing processes, primarily in shaping and producing plastic materials. At the heart of this machinery are several key components that work collaboratively to ensure efficient extrusion.

The hopper is the first essential part, designed to hold and feed plastic pellets into the extruder. It allows for a continuous supply of material, ensuring smooth operation. The feed screw follows, which rotates to push the pellets through the barrel. As the screw turns, it also applies heat and pressure, melting the plastic to a workable consistency. This transformation is crucial, as it prepares the plastic for shaping.

Another vital component is the heater, which maintains the necessary temperature throughout the barrel, ensuring the plastic melts evenly. The die is the final part where the molten plastic takes its final shape before being cut or cooled into specific products. Accurately designed dies allow for a variety of profiles, which can be adjusted based on the requirements of the final product. Each of these components plays a critical role in the functionality of a plastic extruder, contributing to the overall efficiency and versatility of the manufacturing process.

How Plastic Extruders Operate: The Process of Melting and Shaping Materials

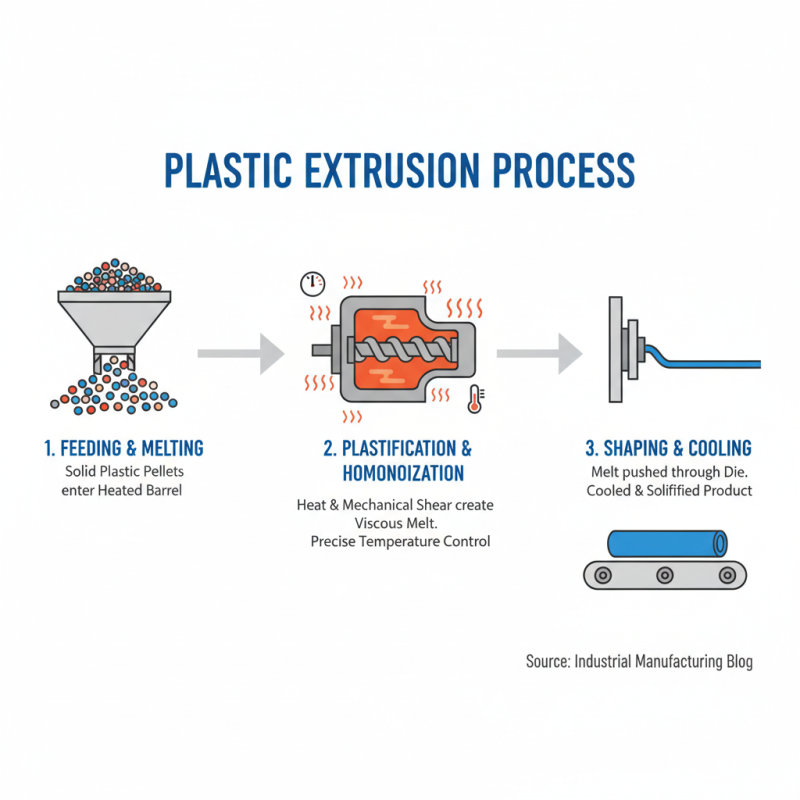

Plastic extruders play a crucial role in the manufacturing process by converting raw plastic materials into usable products through a systematic approach. The operation of a plastic extruder begins with feeding solid plastic pellets into a heated barrel, where they are subjected to both heat and mechanical shear. This combination causes the plastic to melt, transforming it into a viscous state. The temperature control is critical during this phase, as it ensures that the material reaches the right melting point without degrading.

Once the plastic is melted, it is forced through a die, which shapes the material into the desired profile. This shaping process can produce a variety of products, from simple pipes and sheets to more complex profiles. As the molten plastic flows through the die, it cools and solidifies, taking on its final shape. The speed at which the material is extruded, along with the design of the die, determines the dimensions and quality of the final product. This continuous operation allows for the efficient production of plastic components in a range of industries, showcasing the versatility and effectiveness of plastic extruders in modern manufacturing processes.

Applications of Plastic Extruders in Manufacturing: Key Industries and Uses

Plastic extruders play a vital role in various manufacturing processes across multiple industries. The versatility of these machines allows for the production of a wide range of plastic products, including:

- Pipes

- Sheets

- Films

- Profiles

In the packaging industry, plastic extruders are particularly important for producing flexible films that meet stringent quality standards. Reports indicate that approximately 30% of plastic extrusion applications are geared towards packaging, highlighting its significance in catering to consumer goods' ever-evolving demands. Additionally, in the construction sector, plastic extrusion enables the creation of durable and lightweight products, like insulation materials and window frames, contributing to better energy efficiency and sustainability.

Tips for manufacturers considering plastic extrusion: First, evaluate the material compatibility with the extruder to ensure optimal performance and waste reduction. Second, stay updated with the latest extrusion technology advancements to enhance production efficiency and product quality. Finally, consider adopting recycling practices in extrusion processes to align with growing sustainability expectations in the industry.

Future Trends in Plastic Extrusion Technology: Innovations and Impacts on Production

The field of plastic extrusion technology is undergoing transformative changes, driven by both innovations in materials and advancements in processing techniques. One of the key trends is the integration of smart manufacturing practices, such as the Internet of Things (IoT) and artificial intelligence (AI), into extrusion processes. These technologies allow for real-time monitoring and data analysis, which improves efficiency and product quality. Manufacturers can anticipate issues before they occur, leading to reduced waste and energy consumption, and ultimately lowering production costs.

Moreover, the focus on sustainability is reshaping plastic extrusion. Companies are increasingly exploring biodegradable plastics and recycled materials, pushing the boundaries of traditional extrusion applications. These developments not only meet consumer demand for environmentally friendly products but also comply with stricter regulations on waste and recycling. Embracing these sustainable practices can enhance a company's reputation and open up new market opportunities.

***Tips:*** When considering updates to your extrusion process, evaluate your current machinery's compatibility with new technologies. Investing in training for your workforce on these innovations will ensure a smoother transition and maximized productivity. Additionally, keep an eye on regulatory changes that may influence material choices and production methods in your industry.

Future Trends in Plastic Extrusion Technology

This chart represents the adoption rate of plastic extrusion technologies in manufacturing processes over the years from 2020 to 2024. As innovations and improvements in plastic extrusion technology continue to evolve, we can see a significant increase in adoption rates, reflecting a growing trend toward modernization in manufacturing.

Related Posts

-

Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production

-

2025 Top Uses for Layflat Polythene Tubing in Various Industries

-

Top 10 Tips for Choosing the Right Custom Tubing for Your Project

-

Top 10 Benefits of Using Plastic Channel in Your Projects

-

Understanding the Role of PVC Extrusions in Sustainable Building Designs

-

10 Essential Tips for Optimizing Plastic Extrusion Profiles and Enhancing Production Efficiency