What is Layflat Tubing and How is it Used in Various Industries

Layflat tubing is an innovative solution that has revolutionized various industries by providing efficient and versatile options for transporting fluids. As industry expert John Smith, a well-known authority in polymer engineering, states, "Layflat tubing blends practicality with durability, making it ideal for diverse applications." This adaptability makes layflat tubing a preferred choice in sectors ranging from agriculture to construction, and even in wastewater management.

The design of layflat tubing allows it to be easily deployed and retracted, which not only saves space but also enhances the ease of handling. It can be used for irrigation systems to efficiently convey water to crops or to manage floodwaters in construction sites. The lightweight nature of layflat tubing significantly reduces transport costs while maintaining high performance under various pressures.

As we delve deeper into the applications and advantages of layflat tubing, it becomes clear that its significance extends beyond mere utility. This versatile product stands at the intersection of innovation and practicality, providing solutions that meet the demands of modern industries while ensuring sustainability and efficiency. Understanding the full potential of layflat tubing is essential for businesses looking to optimize their operations and embrace future advancements.

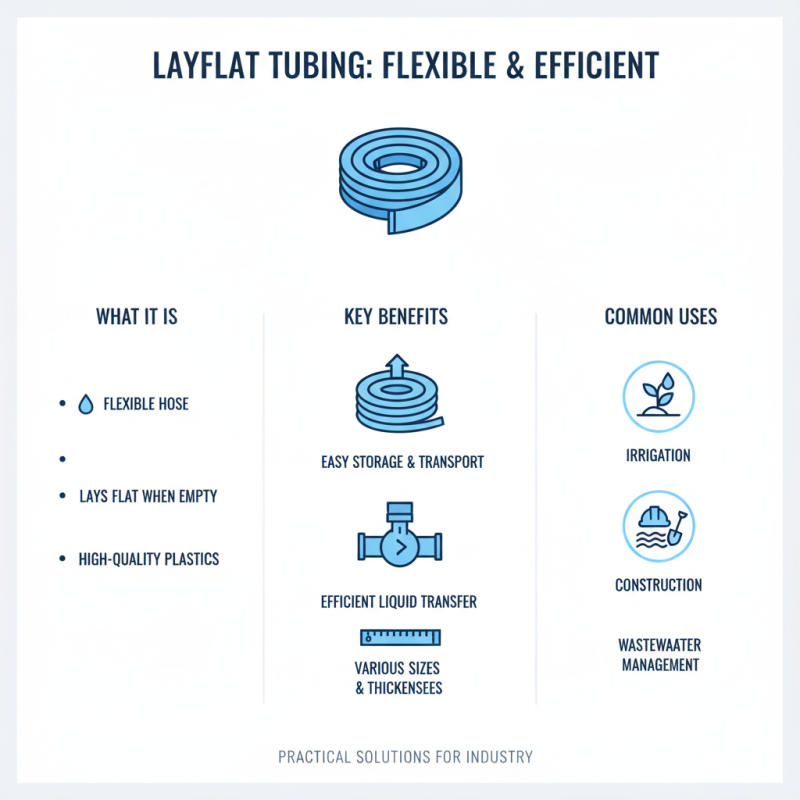

What is Layflat Tubing?

Layflat tubing is a flexible, versatile type of hose that lays flat when not in use, making it a practical choice for various industrial applications. Typically made from high-quality plastics, layflat tubing is designed to handle liquids and is often used for irrigation, construction, and wastewater management. Its flat design allows for easy storage and transportation, reducing the space needed compared to conventional round hoses. Moreover, it is available in various sizes and thicknesses to accommodate different flow rates and pressure requirements.

When using layflat tubing, it's important to consider a few key tips to ensure optimal performance. First, always check the specifications to match the tubing's capabilities with the intended application, especially regarding pressure ratings. Secondly, invest in appropriate fittings and connectors to prevent leaks, which can lead to wastage or safety hazards. Lastly, be mindful of storage conditions; keeping layflat tubing away from extreme temperatures and direct sunlight will extend its lifespan and maintain its effectiveness.

As industries continue to leverage the benefits of layflat tubing, understanding its properties and proper usage can significantly enhance operational efficiency. Its lightweight nature and adaptability make it an essential tool in sectors that require reliable fluid transport solutions.

Materials Used in Layflat Tubing Production

Layflat tubing is produced using a variety of materials that contribute to its versatility and effectiveness in many applications. One of the primary materials utilized in layflat tubing is PVC (polyvinyl chloride), known for its durability and resistance to corrosion. PVC offers excellent performance in both high and low temperatures, making it suitable for diverse environments and operational conditions. Additionally, its lightweight nature facilitates ease of handling and installation, which are crucial factors in industries like agriculture and construction.

Another commonly used material in the production of layflat tubing is polyethylene. This material is notable for its flexibility and tensile strength, which allow the tubing to withstand high pressure and resist punctures. Polyethylene layflat tubing is frequently used in water transportation, irrigation systems, and even as temporary storage solutions for liquids. The combination of polyethylene's attributes with various additives ensures that the tubing can meet specific industry requirements, such as UV resistance and chemical compatibility. Overall, the choice of materials significantly influences the performance and functionality of layflat tubing across multiple sectors.

What is Layflat Tubing and How is it Used in Various Industries - Materials Used in Layflat Tubing Production

| Industry | Common Applications | Materials Used | Benefits |

|---|---|---|---|

| Agriculture | Irrigation systems, water distribution | Polyethylene, PVC | Lightweight, flexible, UV resistant |

| Construction | Water management, drainage | HDPE, LDPE | Durable, easy to transport |

| Mining | Conveying water, slurry pipelines | Nylon, polyester | High tensile strength, chemical resistant |

| Oil and Gas | Fracking, fluid transport | Polypropylene, reinforced composites | Robust, can handle high pressures |

| Event Management | Temporary water lines, pumping | PVC, rubber | Flexible, easy setup and teardown |

Common Applications of Layflat Tubing Across Industries

Layflat tubing, a versatile flexible plastic tube, is widely utilized across various industries due to its durability and adaptability. One of the most common applications is in the agricultural sector, where it is employed for

irrigation systems and fluid transport. Its lightweight and collapsible nature makes it ideal for transporting water efficiently, helping to conserve resources while ensuring crops receive the necessary hydration. Additionally, its resistance to wear and tear under various environmental conditions allows it to withstand the rigors of agricultural tasks.

In the construction industry, layflat tubing serves multiple purposes as well. It is often used for dewatering applications, where water needs to be effectively drained from construction sites. The ability to lay flat makes it easy to transport and deploy in various terrains. Furthermore, its use in the transportation of concrete, aggregates, and other construction materials aids in ensuring that projects adhere to timelines while minimizing labor costs. Overall, the versatility of layflat tubing across these industries highlights its essential role in enhancing operational efficiency and productivity.

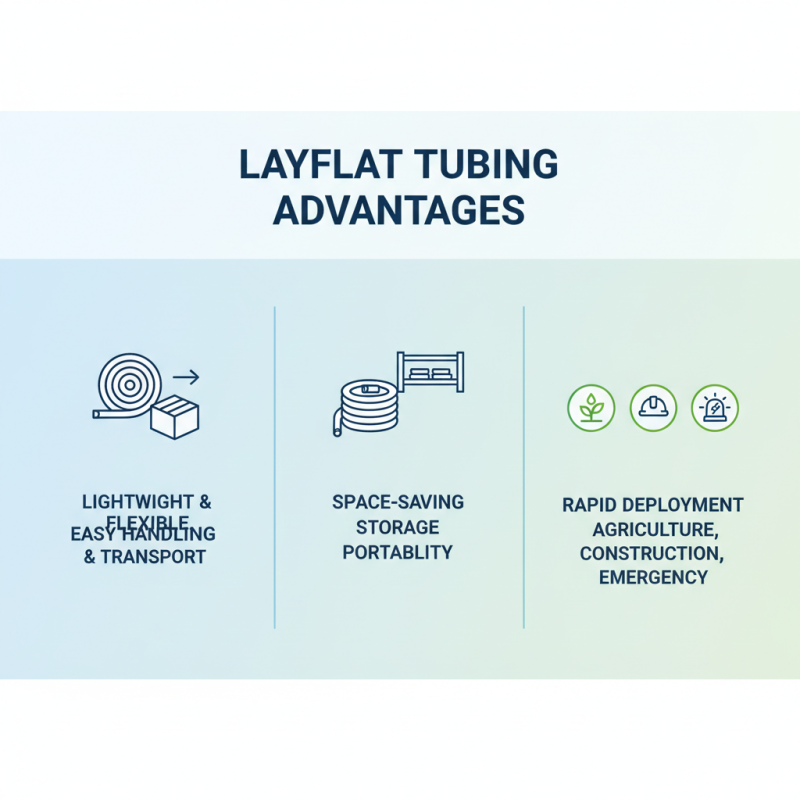

Advantages of Using Layflat Tubing Over Traditional Solutions

Layflat tubing has gained popularity in various industries due to its numerous advantages over traditional solutions. One of the primary benefits is its lightweight and flexible design, which facilitates easier handling and transport. Unlike bulky alternatives, layflat tubing can be easily rolled up and stored, making it ideal for situations where space and portability are crucial. This feature is particularly advantageous in sectors such as agriculture, construction, and emergency response, where rapid deployment and adaptability are often required.

Additionally, layflat tubing offers superior durability and resistance to kinks and punctures, ensuring a longer lifespan in challenging environments. This resilience reduces the frequency of replacements, ultimately leading to cost savings over time. Importantly, layflat tubing's versatility allows it to be used for a wide range of applications, from irrigation systems in farming to fluid transfer in industrial settings. The ability to customize the size and thickness of the tubing further enhances its appeal, allowing businesses to select the right specifications for their specific needs, thus improving overall operational efficiency.

Maintenance and Storage Considerations for Layflat Tubing

When it comes to the maintenance and storage of layflat tubing, proper handling can significantly extend the life and efficiency of the product. Layflat tubing, typically made from PVC or polyurethane, is widely used in agricultural, construction, and industrial applications. According to a recent industry report from Grand View Research, the global layflat hose market is projected to reach USD 1.28 billion by 2028, reflecting the growing demand for reliable irrigation and fluid transfer solutions. This increase underscores the importance of maintaining tubing integrity to ensure it operates effectively.

Proper storage conditions are vital for layflat tubing. Exposure to extreme temperatures or direct sunlight can lead to material degradation, compromising the hose's strength and flexibility. The American Society for Testing and Materials (ASTM) suggests storing layflat tubing in a cool, dry place, away from direct UV exposure to avoid material brittleness and premature failure. Additionally, it is recommended to coil the tubing gently without kinks, which can lead to collapse or leakage points. Regular inspections and maintenance routines, including checking for signs of wear or damage and cleaning the hoses after use, further contribute to their longevity and reliability in various applications.

Layflat Tubing Usage Across Industries

This chart illustrates the percentage of layflat tubing usage across various industries, highlighting its significance and versatility in applications like agriculture, construction, mining, water management, and transportation.

Related Posts

-

Exploring the Benefits of Plastic Hinges: Durability and Cost-Efficiency in Modern Applications

-

Top 10 Benefits of Using Plastic Channel in Your Projects

-

Exploring the Benefits of Plastic Channels in Modern Infrastructure Development

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions

-

2025 Top 5 PVC Extrusion Profiles for Durable and Versatile Applications

-

Unlocking the Benefits of PVDF Tubing: Why It’s the Future of Industrial Solutions