Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production

In the rapidly evolving landscape of manufacturing, understanding the latest innovations in plastic extruder technology is crucial for enhancing production efficiency.

Plastic extruders play a pivotal role in shaping a wide range of products, from simple components to complex structures, by converting polymer materials into functional forms. This introduction explores how modern advancements in plastic extruder design and functionality are addressing industry demands for higher throughput, energy efficiency, and material versatility.

As businesses strive to optimize their production processes, the significance of adopting cutting-edge plastic extruder technologies cannot be overstated.

Plastic extruders play a pivotal role in shaping a wide range of products, from simple components to complex structures, by converting polymer materials into functional forms. This introduction explores how modern advancements in plastic extruder design and functionality are addressing industry demands for higher throughput, energy efficiency, and material versatility.

As businesses strive to optimize their production processes, the significance of adopting cutting-edge plastic extruder technologies cannot be overstated.

By delving into these innovations, manufacturers can not only improve their operational performance but also stay competitive in a market that increasingly values sustainability and quality. This guide will provide insights on how to leverage these technological advancements for efficient production, ensuring that organizations can make informed decisions in a fast-paced industry.

How to Select the Right Plastic Extruder for Your Production Needs

When selecting the right plastic extruder for your production needs, it is crucial to consider several key factors that can significantly impact efficiency and output quality. According to a 2023 industry report by Smithers Pira, the global demand for plastic extruders is projected to grow at a CAGR of 4.5%, primarily driven by advancements in technology and innovations in materials. Understanding the specific types of extruders available, such as single-screw, twin-screw, and multi-screw extruders, can help manufacturers match their production requirements with the most suitable equipment.

Moreover, the choice of extruder must align with the intended application, whether it’s for film production, pipe extrusion, or profile shaping. Recent studies indicate that twin-screw extruders are gaining popularity due to their increased efficiency and versatility, providing up to 25% higher output compared to traditional single-screw models. Additionally, features such as temperature control, feed rate, and screw design should be evaluated, as they directly influence the material processing characteristics and overall production efficiency. By carefully analyzing these factors, manufacturers can enhance their production capabilities and minimize operational costs effectively.

Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production - How to Select the Right Plastic Extruder for Your Production Needs

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| High Output Rate | Designs optimized for faster production times. | Increased productivity and efficiency in manufacturing. | Requires careful selection of materials to prevent overheating. |

| Energy Efficiency | Use of advanced motors and controls to reduce energy consumption. | Lower operational costs and reduced carbon footprint. | Initial investment may be higher for efficient models. |

| Modular Design | Interchangeable components for customization. | Flexibility to adapt to different production needs. | Maintenance can be complex with modular systems. |

| Advanced Control Systems | Integration of IoT and smart technology for real-time monitoring. | Improved quality control and automation capabilities. | Requires staff training for effective use of advanced systems. |

| Material Versatility | Ability to process a wide variety of plastics and composites. | Greater versatility in product offerings. | Compatibility with specific materials may vary. |

How to Optimize Process Parameters for Enhanced Extrusion Efficiency

The latest advancements in plastic extruder technology are focused on optimizing process parameters to enhance extrusion efficiency, which is essential for boosting production rates and maintaining quality. By fine-tuning variables such as temperature, pressure, and screw design, manufacturers can significantly improve the melt flow and reduce energy consumption. According to industry reports, optimizing these parameters can lead to a 15-30% increase in production efficiency, demonstrating the critical need for continual investment in technology and innovation.

Moreover, integrating smart technologies into extruder operations can further enhance efficiency. For example, real-time monitoring systems allow for immediate adjustments based on processing conditions, minimizing material waste and ensuring consistent product quality. Data from recent studies reveal that companies employing such smart solutions achieve up to 25% higher operational efficiency compared to traditional methods. As the industry evolves, focusing on these innovations and process optimizations will pave the way for a more sustainable and productive future in plastic extrusion.

How to Integrate Advanced Control Systems in Plastic Extruders

In recent years, the integration of advanced control systems in plastic extruders has become a focal point for manufacturers aiming to enhance production efficiency. According to a market analysis report by Grand View Research, the global market for plastic extrusion machines is expected to reach USD 8.53 billion by 2025, driven partly by the adoption of smart technologies. These advanced control systems enable real-time monitoring and adjustment of the extrusion process, which minimizes material waste and optimizes energy consumption.

Moreover, the implementation of Industry 4.0 principles in plastic extruders allows for more precise management of production parameters. For instance, the use of IoT sensors and machine learning algorithms helps in predictive maintenance, reducing downtime and enhancing operational reliability. A study published by the Journal of Manufacturing Science and Engineering noted that companies integrating such technologies have reported efficiency gains of up to 30%. This trend underscores the importance of investing in sophisticated control systems not just for competitive advantage but also for sustainable production in the plastic industry.

How to Implement Sustainable Practices in Plastic Extrusion Operations

Sustainable practices in plastic extrusion operations are increasingly vital as industries seek to minimize their environmental impact while maintaining efficiency. Implementing innovations in equipment design and production processes can lead to significant reductions in waste and energy consumption. For instance, using energy-efficient extruders can cut operational costs and reduce the carbon footprint of the plastic production process. Technologies that enable better material handling and recycling can also enhance sustainability, allowing manufacturers to utilize recycled materials effectively and reduce reliance on virgin plastics.

Another key component of sustainable practices is the adoption of biodegradable additives and eco-friendly polymers in extrusion processes. These advancements not only help manufacturers meet regulatory requirements but also align with consumer demand for greener products. The integration of smart technologies, such as IoT sensors for monitoring machine performance and material usage, allows for more precise control over production processes, further enhancing the sustainability of operations. As the market for extruders is projected to grow steadily, embracing these sustainable practices will be essential for companies looking to thrive in a changing economic landscape.

How to Stay Ahead of Trends in Plastic Extruder Technology Innovations

To stay ahead in the rapidly evolving landscape of plastic extruder technology, companies must focus on both research and market trends. Recent reports highlight the growth trajectory of the plastic machinery industry, with significant revenue increases noted in companies that are leveraging dual strategies of innovation and market expansion. For example, a recent quarterly report indicated a 12.05% year-over-year revenue increase, showcasing how responsive strategies can enhance performance even amidst global economic challenges.

As the global market for extruders and compounders is projected to reach 9.4 billion USD by 2024, innovations in technology are crucial. With a compound annual growth rate of 4.2% expected until 2033, staying abreast of the latest advancements is essential for manufacturers. Companies must invest in research and development to innovate their product offerings continuously. By cultivating agility and a forward-thinking approach, businesses can not only respond to current trends but also anticipate future demands in the plastic extrusion sector.

Understanding the Latest Innovations in Plastic Extruder Technology

This chart illustrates the percentage increase in efficiency and production volume associated with various innovations in plastic extruder technology over the past few years.

Related Posts

-

Exploring the Benefits of Plastic Hinges: Durability and Cost-Efficiency in Modern Applications

-

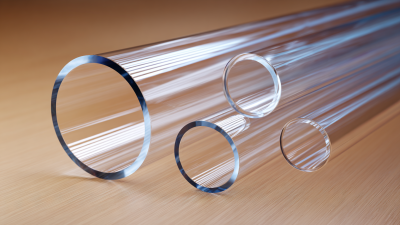

How to Choose the Best Polycarbonate Tube for Your DIY Projects and Home Improvements

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions

-

Exploring the Benefits of Plastic Channels in Modern Infrastructure Development

-

Unlocking the Benefits of PVDF Tubing: Why It’s the Future of Industrial Solutions