10 Essential Tips for Optimizing Plastic Extrusion Profiles and Enhancing Production Efficiency

In the rapidly evolving world of manufacturing, optimizing plastic extrusion profiles is crucial for not just enhancing production efficiency but also ensuring the quality of the final products. As noted by industry expert Dr. Emily Carter, "The effectiveness of our extrusion processes defines the competitiveness of our products in the marketplace." With the increasing demand for precision and customization in plastic components, the importance of refining extrusion techniques has never been more significant.

The plastic extrusion industry continues to face challenges, including material waste and energy consumption, which necessitate innovative solutions and best practices. By focusing on the fine-tuning of plastic extrusion profiles, manufacturers can successfully minimize these limitations while maximizing output. The integration of cutting-edge technologies and methodologies will empower businesses to stay ahead in this competitive landscape, driving sustainable practices and greater profitability.

In this article, we will explore ten essential tips aimed at optimizing plastic extrusion profiles, ensuring that manufacturers not only meet but exceed production efficiency standards. Whether you are a seasoned professional or new to the field, these insights will serve as a valuable guide in navigating the complexities of plastic extrusion and enhancing overall operational success.

Understanding the Fundamentals of Plastic Extrusion for Better Optimization

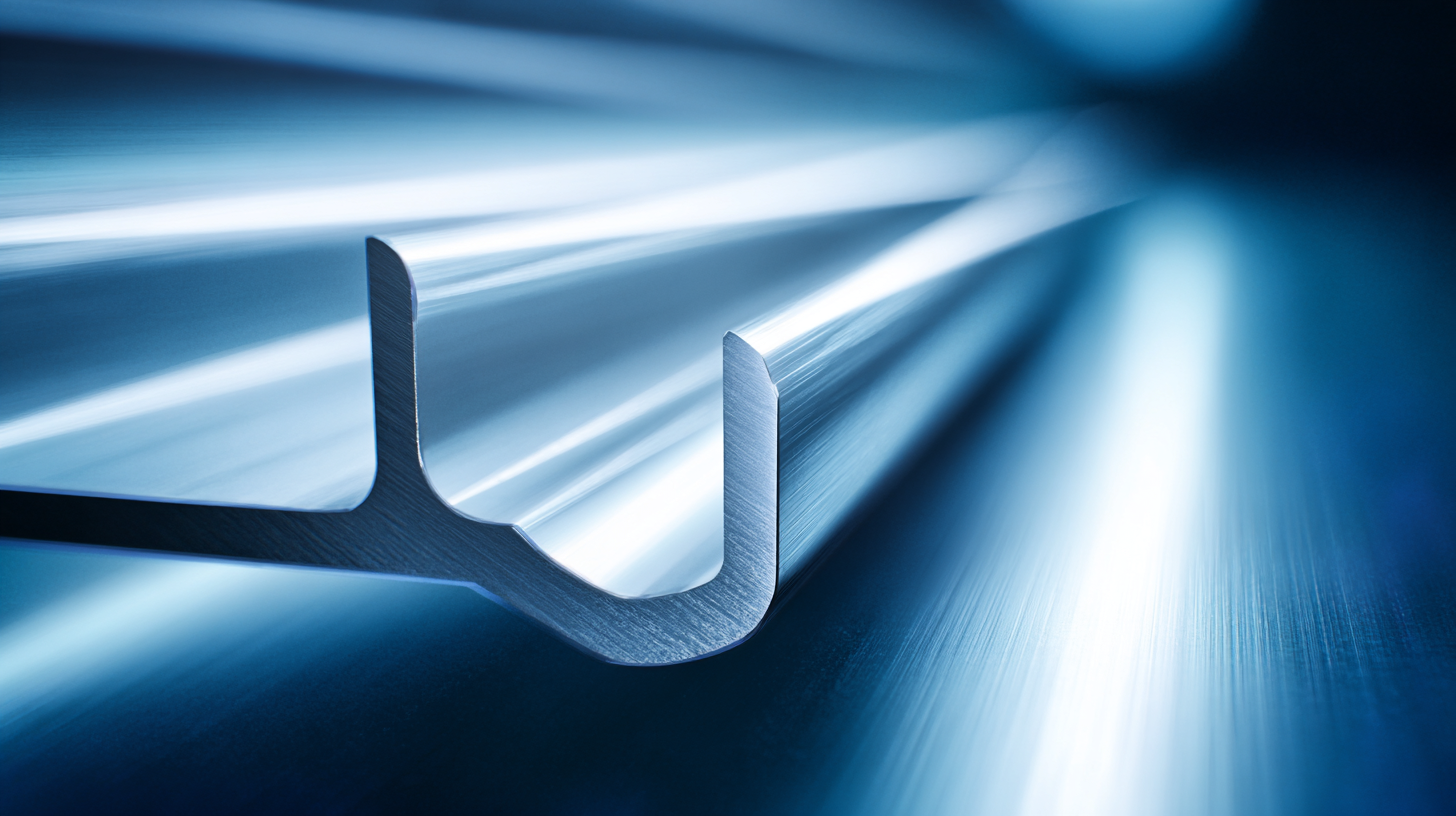

Plastic extrusion is a crucial manufacturing process that shapes melted plastic into a continuous profile, which can then be cooled and cut to size. Understanding the fundamentals of this process is essential for optimizing production efficiency. Factors such as temperature control, material selection, and die design play significant roles in achieving high-quality extrusions. Properly managing the temperature of the extruder ensures that polymers reach their optimal melting point, thereby minimizing degradation and maximizing flow consistency through the die.

Plastic extrusion is a crucial manufacturing process that shapes melted plastic into a continuous profile, which can then be cooled and cut to size. Understanding the fundamentals of this process is essential for optimizing production efficiency. Factors such as temperature control, material selection, and die design play significant roles in achieving high-quality extrusions. Properly managing the temperature of the extruder ensures that polymers reach their optimal melting point, thereby minimizing degradation and maximizing flow consistency through the die.

Moreover, the choice of materials significantly influences the properties of the final product. Selecting the right type of plastic for specific applications not only improves performance but also enhances the output quality. Die design is another essential component; a well-designed die can help reduce pressure drops and ensure uniform flow, leading to better dimensional accuracy and surface finish. By focusing on these fundamentals, manufacturers can implement targeted strategies for optimizing their extrusion profiles, resulting in improved production efficiency and reduced waste.

Key Techniques for Designing Efficient Extrusion Profiles

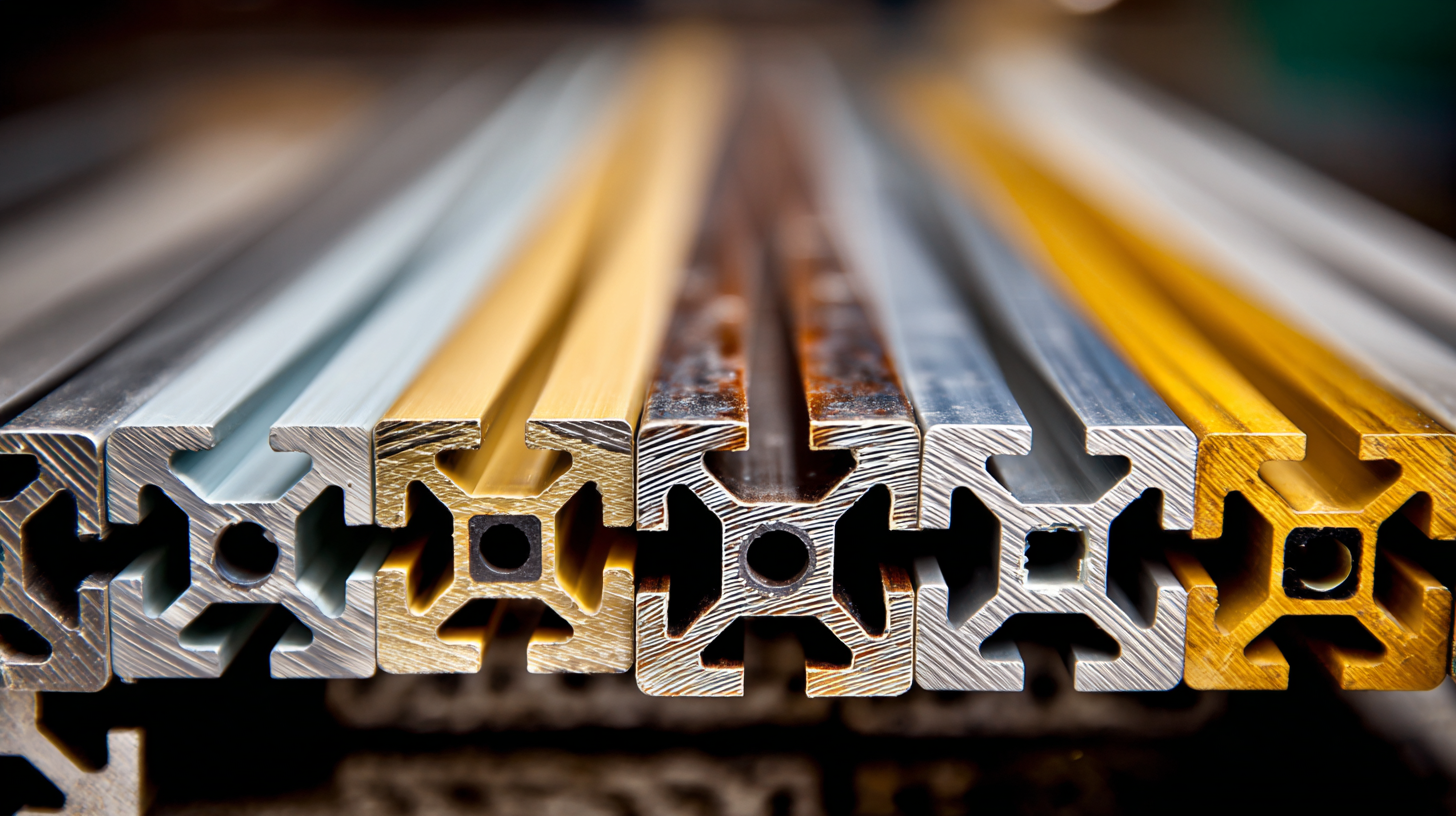

Designing efficient extrusion profiles is paramount for optimizing plastic extrusion processes. A well-designed profile not only ensures material efficiency but also enhances the overall production speed. One key technique is to minimize sharp corners in the profile design. Sharp angles tend to create turbulence in the material flow, which can lead to uneven wall thickness and defects. By incorporating smooth transitions and radii, manufacturers can achieve a more consistent material flow and reduce the risk of defects.

Another important aspect is the selection of the appropriate die and tooling. The die design should complement the specific material being used, taking into account its viscosity and flow characteristics. Additionally, maintaining optimal temperature control within the die can prevent overheating and ensure that the material maintains its integrity throughout the extrusion process. Regular maintenance and calibration of equipment also play a crucial role in ensuring that the profiles are extruded accurately and efficiently, reducing downtime and material waste. By focusing on these design techniques, producers can significantly enhance the efficiency of their extrusion processes.

Importance of Material Selection in Enhancing Production Efficiency

Choosing the right material for plastic extrusion is critical for optimizing production efficiency. According to a report by the Plastics Industry Association, the selection of high-quality polymers can lead to a 20% increase in production rates and significantly reduce downtime associated with material incompatibility. For instance, high-density polyethylene (HDPE) is often preferred for its excellent flow properties and resilience, which can enhance the overall quality of the extruded profiles while minimizing waste.

In addition to material properties, the compatibility of additives and fillers plays a vital role in production efficiency. A study by the Society of Plastics Engineers revealed that incorporating well-selected additives can improve mechanical properties and processability, thereby boosting production speed by up to 15%. Moreover, understanding the thermal and rheological characteristics of chosen materials allows for better control during the extrusion process, which reduces the likelihood of defects and rework. Prioritizing material selection not only streamlines the production process but ultimately leads to higher quality outputs and cost savings in the long run.

10 Essential Tips for Optimizing Plastic Extrusion Profiles and Enhancing Production Efficiency

| Tip No. | Tip | Material Consideration | Impact on Efficiency |

|---|---|---|---|

| 1 | Optimize Die Design | Material Flow Characteristics | Improves uniformity and reduces waste |

| 2 | Control Extrusion Temperature | Thermal Properties of Material | Enhances material flow and reduces defects |

| 3 | Adjusting Screw Speed | Viscosity of Material | Increases output rate and consistency |

| 4 | Proper Cooling Techniques | Thermal Conductivity | Reduces cycle time and improves quality |

| 5 | Regular Maintenance of Equipment | Durability of Components | Minimizes downtime and increases reliability |

| 6 | Monitor Material Input Quality | Purity and Consistency | Ensures optimal extrusion performance |

| 7 | Utilize Automated Systems | Integration Capability | Increases overall operational efficiency |

| 8 | Conduct Training for Operators | Skill Level of Personnel | Improves production accuracy and quality |

| 9 | Implement Quality Control Checks | Properties of End Material | Reduces scrap rates and enhances quality |

| 10 | Streamline Workflow Procedures | Material Handling Efficiency | Increases production throughput |

Implementing Regular Maintenance for Optimal Machine Performance

Maintaining optimal machine performance is crucial for enhancing production efficiency in plastic extrusion processes. Regular maintenance schedules help to identify potential issues before they escalate into major problems. This proactive approach not only extends the lifespan of the machinery but also ensures consistent quality in the products being extruded. By integrating routine checks into daily or weekly operations, operators can address wear and tear on essential components such as screws, barrels, and heating elements, thus preventing unplanned downtime.

Moreover, investing in training for the maintenance team is essential. Well-informed technicians can quickly spot irregularities and carry out repairs effectively, minimizing disruptions. This not only keeps the extrusion machines running smoothly but also fosters a culture of diligence where every team member understands the importance of equipment care. Regular maintenance, combined with comprehensive training, creates a reliable foundation for achieving optimal production outcomes and enhances overall operational efficiency in the plastic extrusion process.

Utilizing Data Analytics to Monitor and Improve Production Processes

Utilizing data analytics in the realm of plastic extrusion profiles can significantly enhance production efficiency. By implementing advanced data collection methods, manufacturers can gather crucial insights into every stage of the extrusion process. This allows for real-time monitoring of parameters such as temperature, pressure, and material flow rates. With these metrics at their fingertips, operators can quickly identify deviations or inefficiencies that may arise during production, enabling proactive adjustments to maintain optimal performance.

Moreover, data analytics facilitates trend analysis over time, helping manufacturers pinpoint recurring issues that may not be apparent in real-time monitoring alone. By analyzing historical data, businesses can uncover patterns that lead to defects or downtime. Implementing machine learning algorithms can further refine these insights, predicting potential failures before they occur and reducing waste. As the industry moves towards smarter manufacturing practices, leveraging data analytics will not only improve quality but also streamline operations, ultimately achieving a more efficient and cost-effective production environment.

Related Posts

-

Innovative Techniques in Plastic Extrusion Transforming Manufacturing for the Future

-

Understanding the Role of PVC Extrusions in Sustainable Building Designs

-

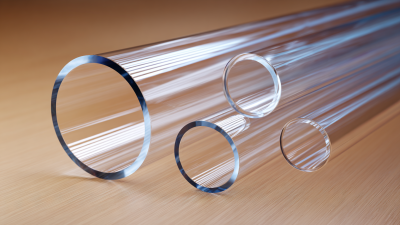

Top 10 Benefits of Using Clear Acrylic Tubes: Why This Material Dominates the Market in 2023

-

How to Choose the Best Polycarbonate Tube for Your DIY Projects and Home Improvements

-

How to Choose the Right Plastic Hinges for Your Project Needs

-

Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production