How to Choose the Right Plastic Hinges for Your Project Needs

When it comes to selecting the right plastic hinges for your project needs, understanding the various types available and their specific applications is crucial. As industry expert Dr. Sarah Thompson, a leading authority on materials engineering, once stated, “Choosing the appropriate plastic hinge not only enhances the functionality of your project but also contributes significantly to its longevity and overall aesthetic.” This insight emphasizes the importance of making informed decisions when it comes to plastic hinges.

Plastic hinges are increasingly favored in a wide range of industries due to their lightweight nature, resistance to corrosion, and versatility. However, with so many options on the market, the challenge lies in identifying which type is the best fit for your particular requirements. Factors such as load capacity, environmental conditions, and intended use must be taken into account to ensure optimal performance.

Moreover, the evolution of plastic hinge technology has led to innovations that provide enhanced durability and design flexibility. Understanding the nuances of each type of plastic hinge allows designers and engineers to make choices that align with their project goals. As we delve deeper into the various categories and specifications of plastic hinges, we aim to equip you with the knowledge needed to make the best selection for your next project.

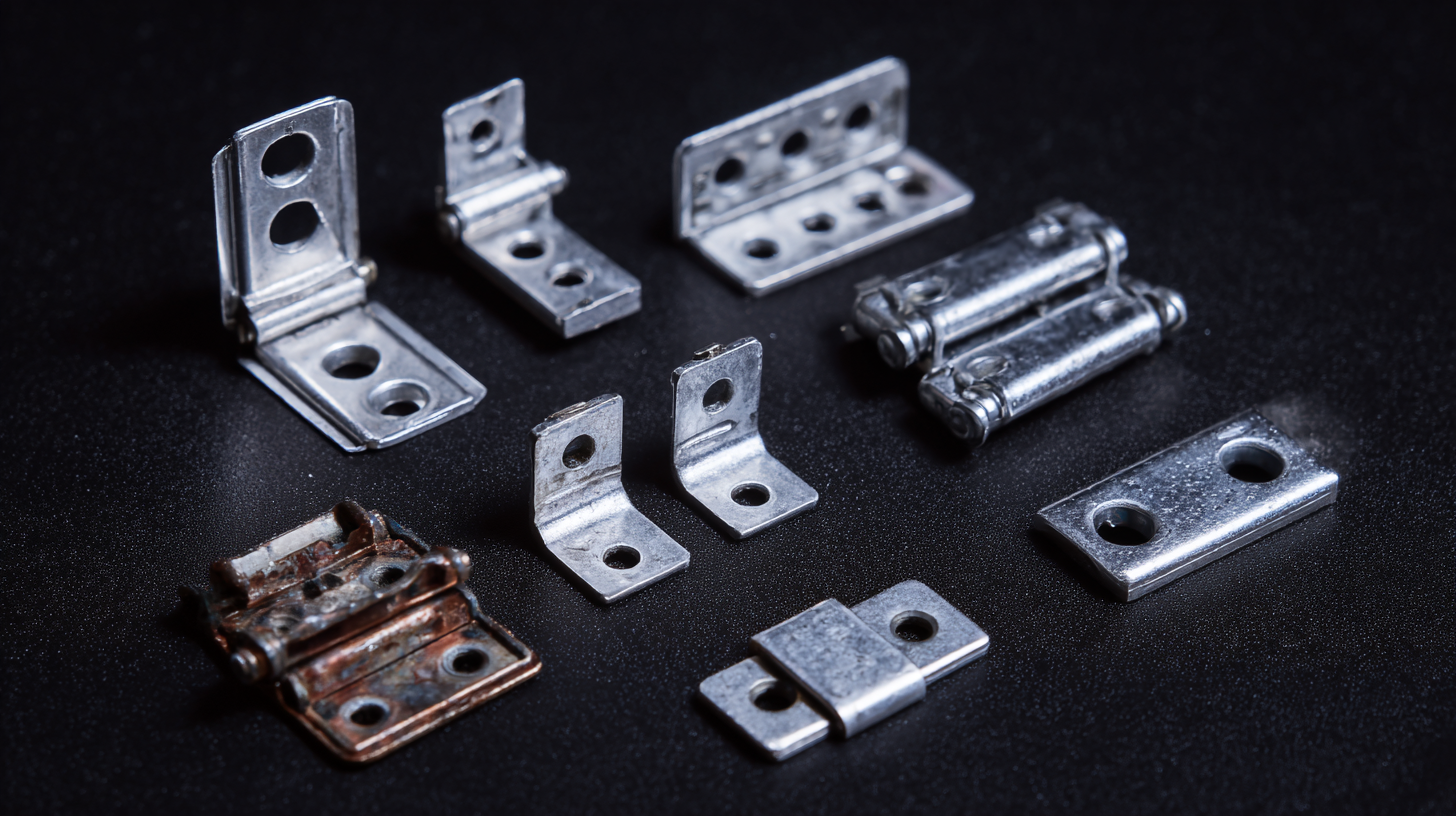

Identifying the Different Types of Plastic Hinges Available for Projects

When selecting the right plastic hinges for your project, it’s essential to understand the various types that are available. Common options include butt hinges, continuous hinges, and piano hinges, each serving different functional and aesthetic requirements. Butt hinges are ideal for door applications, providing a sturdy connection, while continuous hinges offer consistent support along the entire length, making them perfect for long doors or panels. Piano hinges, on the other hand, are versatile and can be used in a range of applications from musical instruments to toolboxes.

In light of the current environmental challenges related to plastic waste, it is also crucial to consider the material used in plastic hinges. Innovations in AI-driven recycling technologies are beginning to change how plastic waste is processed. By identifying and sorting various plastics more efficiently, AI can help reduce the environmental impact of plastic hinges and promote the use of sustainable materials. Selecting hinges that can be recycled or that are made from recycled materials aligns with responsible project practices and supports broader efforts to tackle plastic waste challenges.

Factors to Consider When Selecting Plastic Hinges for Specific Applications

When selecting plastic hinges for specific applications, several crucial factors must be considered to ensure optimal performance and durability. First and foremost, the intended application is vital. For example, hinges used in environments where cleanliness and hygiene are paramount, such as in food service or medical settings, should be made from non-porous, easy-to-clean materials. Additionally, the load-bearing capacity of the hinge should match the weight of the door or cover it will support. Selecting a hinge that can withstand the anticipated load is essential to prevent failure and prolong the lifespan of the installation.

Another important factor is the environmental conditions where the hinge will be utilized. Plastic hinges come in various formulations suited for different temperatures and exposure to chemicals. For outdoor applications, UV resistance is critical to prevent degradation from sunlight. Similarly, if the hinges will be subjected to aggressive chemicals or moisture, choosing a corrosion-resistant plastic that can handle such conditions will enhance their longevity. Considering these factors ensures that the right plastic hinge is chosen, leading to better functionality and reduced maintenance over time.

Comparing Material Strength and Durability in Plastic Hinges

When choosing plastic hinges for your project, understanding the material strength and durability is crucial. Plastic hinges are commonly made from various types of materials, including polycarbonate, polypropylene, and nylon. Each material has unique properties that affect its performance in different environments. For instance, polycarbonate is renowned for its high impact resistance and can withstand extreme temperatures, making it an excellent choice for outdoor applications or areas subject to heavy use. On the other hand, polypropylene offers good chemical resistance and is often preferred in settings where exposure to harsh substances is likely.

Durability is not solely about strength; it also involves fatigue resistance and the ability to maintain functionality over time. Nylon hinges can provide excellent wear resistance and are suitable for applications that require frequent movement. However, they may not perform as well in high-temperature environments. By evaluating the specific demands of your project—such as load-bearing requirements, exposure to chemicals, and environmental conditions—you can select the appropriate plastic hinge material that ensures longevity and reliability in your application. Lastly, considering the manufacturing process of these hinges can also provide insights into their overall quality and performance in real-world scenarios.

Understanding Weight Limitations and Load Requirements for Plastic Hinges

When selecting plastic hinges for your project, understanding weight limitations and load requirements is crucial. Each plastic hinge is designed to support specific weights, which varies depending on its material composition and design. For example, polypropylene hinges might be suitable for lighter applications, while reinforced nylon hinges are better for heavier loads. Evaluate the maximum load capacity indicated by the manufacturer, ensuring it aligns with your project requirements to prevent hinge failure or malfunction.

Furthermore, it’s essential to consider the operational environment of the hinges. Factors such as temperature fluctuations, exposure to moisture, and potential chemicals can impact the performance of plastic hinges under load. For instance, if the project is in a humid environment, opting for corrosion-resistant materials is advisable. Additionally, understanding dynamic loads versus static loads will help in choosing the right hinge, as dynamic loads typically require a stronger hinge due to the forces exerted during movement. By thoroughly assessing these factors, you can select plastic hinges that will maintain functionality and safety throughout the lifespan of your project.

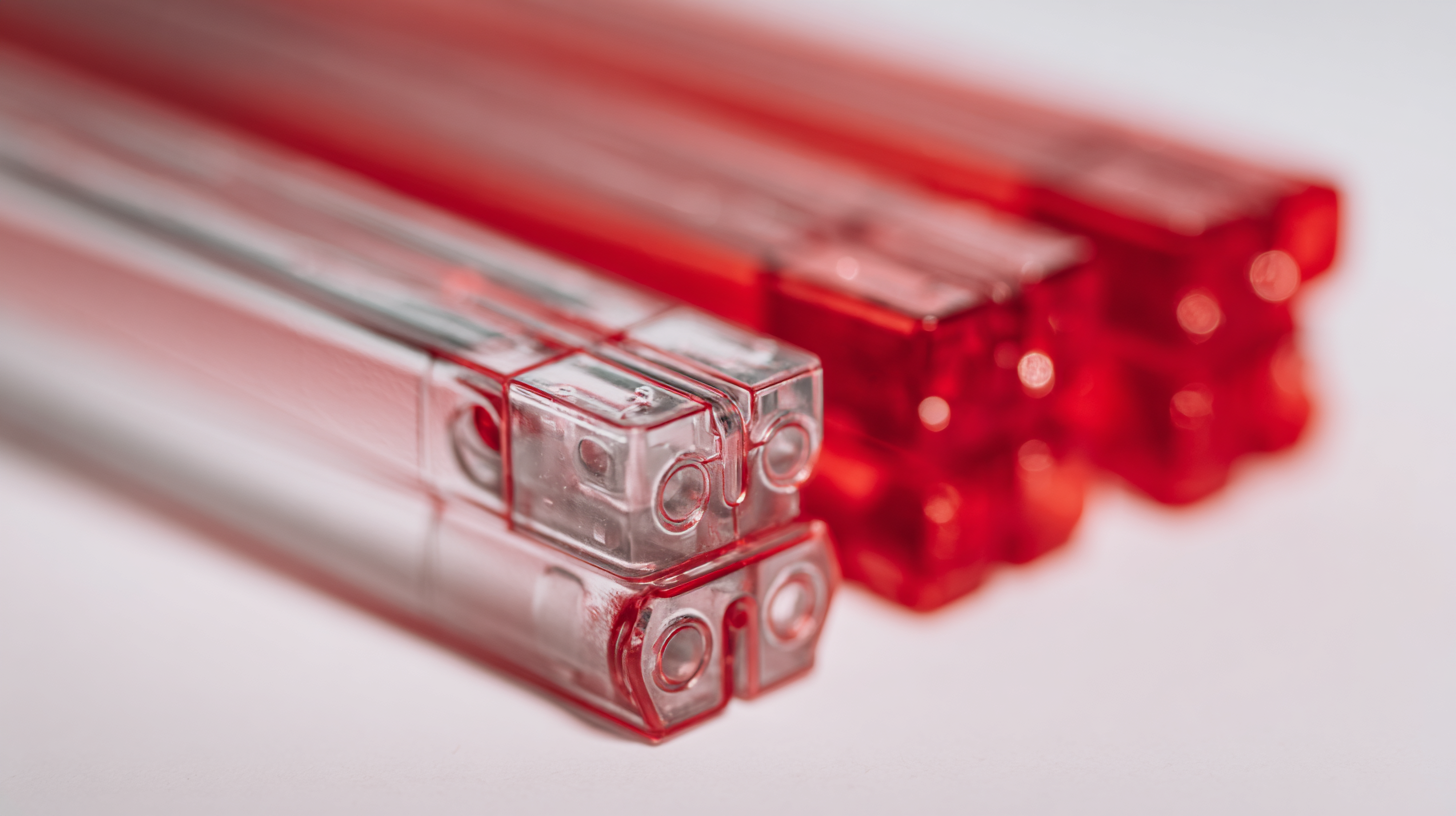

Exploring Aesthetic Options and Finishes for Plastic Hinge Selection

When selecting plastic hinges, aesthetic options and finishes should be a top priority, as they can drastically influence the overall look and functionality of a project. According to a report by Smithers Pira, the demand for aesthetically appealing and durable plastic products in the construction and manufacturing sectors has surged by over 15% annually. This trend highlights the necessity for designers and engineers to consider not only the functional aspects of plastic hinges but also how their appearance can integrate with surrounding materials and overall design themes.

Choosing the right finish is equally important, as it can impact durability and maintenance. For instance, hinges with UV-resistant coatings can significantly extend their lifespan in outdoor applications, reducing replacement needs by up to 20%, as noted in a recent market analysis by Freedonia Group. Additionally, options such as matte, gloss, or textured finishes can enhance grip and contribute to the visual aesthetics, giving projects a polished, professional look that caters to both form and function. With these considerations, making an informed decision about plastic hinge aesthetics can elevate product design and performance significantly.

How to Choose the Right Plastic Hinges for Your Project Needs - Exploring Aesthetic Options and Finishes for Plastic Hinge Selection

| Hinge Type | Material | Finish Options | Load Capacity (lbs) | Ideal Applications |

|---|---|---|---|---|

| Standard Plastic Hinge | Polypropylene | Matte, Glossy | 50 | Cabinet doors, lightweight enclosures |

| Heavy-Duty Plastic Hinge | Polycarbonate | Textured, UV-resistant | 150 | Industrial containers, outdoor applications |

| Adjustable Plastic Hinge | ABS Plastic | Paintable, Custom Colors | 100 | Furniture, custom builds |

| Concealed Plastic Hinge | Nylon | Satin Finish, Transparent | 75 | Doors, cabinetry |

| Continuous Plastic Hinge | PVC | Smooth, Flexible | 200 | Heavy doors, large panels |

Related Posts

-

Exploring the Benefits of Plastic Hinges: Durability and Cost-Efficiency in Modern Applications

-

Understanding the Role of PVC Extrusions in Sustainable Building Designs

-

Top 10 Benefits of Using Clear Acrylic Tubes: Why This Material Dominates the Market in 2023

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions

-

Innovative Ways to Use Layflat Polythene Tubing in Your Next Project

-

Unlocking the Benefits of PVDF Tubing: Why It’s the Future of Industrial Solutions