Top 10 Tips for Choosing the Right Custom Tubing for Your Project

Choosing the right custom tubing for a project demands careful consideration of various factors that can significantly impact

performance and

efficiency. According to a 2022 report by the Global Tubing Group, the custom tubing market is projected to grow by

7.5% annually over the next five years, reflecting the increasing demand across industries such as

pharmaceuticals,

aerospace, and

automotive. These sectors often require tailored solutions to meet specific operational needs, which underscores the importance of selecting the appropriate

material, dimensions, and design characteristics for custom tubing applications.

Expert in the field, Dr. Emily Carter, a leading authority on advanced materials, emphasizes that

"the success of any project relying on custom tubing hinges on understanding the unique requirements of the application and choosing materials that will provide not just durability but also the right mechanical performance."This insight highlights the necessity for stakeholders to gather comprehensive knowledge about their project requirements and to collaborate closely with suppliers to ensure that the custom tubing solutions align perfectly with their operational goals. As we delve into the top 10 tips for selecting the right custom tubing, it is crucial to keep in mind the specific application needs, industry standards, and future scalability options.

Understanding the Specific Requirements of Your Project

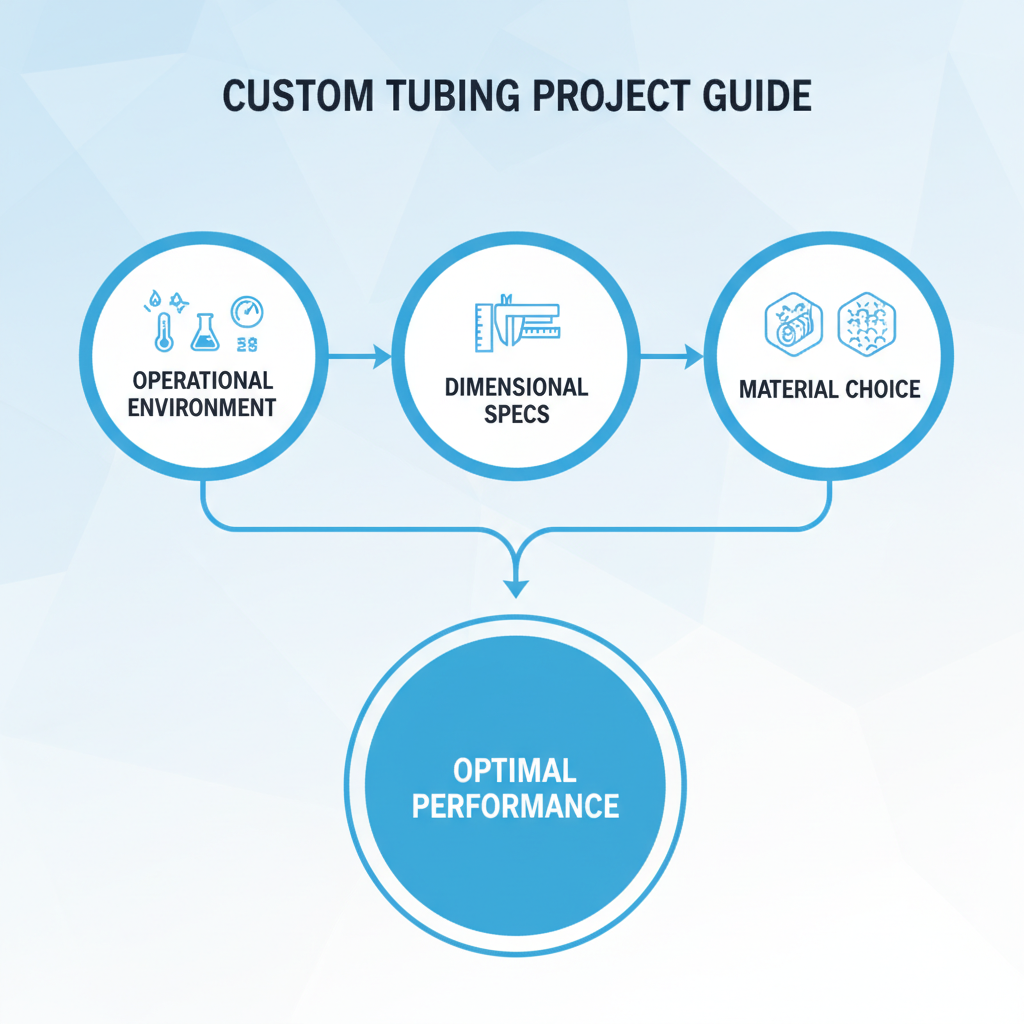

When embarking on a project that requires custom tubing, it’s essential to clearly understand the specific requirements that will guide your decision-making process. Start by assessing the operational environment where the tubing will be used. Consider factors such as temperature, pressure, and exposure to chemicals, which can significantly influence the material choice. Additionally, the dimensional specifications of the tubing, including diameter, wall thickness, and length, must align with the project's design parameters to ensure optimal performance.

Another critical aspect is the intended application of the tubing. Different applications may call for varying flexibility, strength, or rigidity. For instance, medical equipment may require sterile, flexible tubing, while automotive applications might necessitate sturdy, high-temper-resistant materials. Collaborating with engineers or specialists early in the planning phase can help clarify these needs, allowing for a more informed decision that aligns with both project goals and safety standards. By prioritizing these specific requirements, you can select custom tubing that enhances your project’s efficiency and reliability.

Evaluating Different Materials for Custom Tubing

When it comes to custom tubing, selecting the right material is paramount to the success of your project. Various materials offer unique properties that can significantly impact performance, durability, and cost. For instance, according to a 2022 report by the Plastics Industry Association, demand for PVC tubing has soared due to its excellent resistance to chemicals and moisture, making it ideal for both industrial and residential applications. This material can withstand temperatures ranging from -10°F to 140°F, providing versatility in diverse environments.

Moreover, stainless steel tubing is favored for its strength and corrosion resistance, especially in sectors like pharmaceuticals and food processing. A recent study by MarketsandMarkets indicates that the global stainless steel tubing market is projected to reach $3.1 billion by 2026, driven by increasing demand in various industrial applications. Additionally, when considering factors such as flexibility and weight, materials like polyurethane and polyethylene are gaining traction, particularly in medical and automotive fields. Evaluating these properties against the specific requirements of your project will ensure you select the optimal tubing solution that meets both performance and budgetary needs.

Top 10 Tips for Choosing the Right Custom Tubing for Your Project

Assessing the Importance of Size and Dimensions

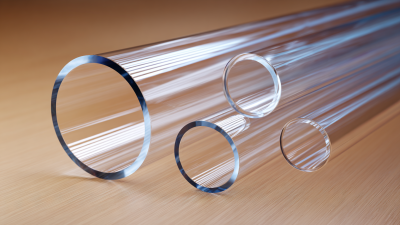

When selecting custom tubing for your project, assessing the importance of size and dimensions is crucial. The right diameter and wall thickness ensure not only the functional performance of the tubing but also its ability to withstand the specific pressures and stresses imposed by your application. For example, if you’re working with fluid transport, the inner diameter must be adequate to allow for optimal flow rates while avoiding excessive turbulence.

Moreover, the length of the tubing plays a significant role in the overall design. Depending on the layout of your project, longer tubing might introduce unwanted bends or kinks, which can hamper performance. Additionally, size considerations must incorporate tolerances and fit; whether the tubing needs to connect seamlessly with other components or fit within confined spaces can greatly influence your choice. By carefully evaluating these dimensions, you can ensure that your custom tubing not only meets the functional requirements but also integrates smoothly into your overall project design.

Choosing the Right Manufacturer for Quality Production

When embarking on a project that requires custom tubing, selecting the right manufacturer is crucial for ensuring quality production. According to the Fabricators & Manufacturers Association (FMA), over 68% of businesses in the metalworking sector cite supplier quality as a top priority when purchasing components. This statistic emphasizes the need for thorough research when evaluating potential manufacturers. High-quality tubing not only meets specific project requirements, but also contributes to the overall integrity and reliability of the final product.

Moreover, it is essential to assess manufacturers based on their technological capabilities and certifications. A report by the International Organization for Standardization (ISO) indicates that companies with ISO 9001 certification demonstrate a consistent commitment to quality management principles, which can significantly reduce production defects. By choosing a manufacturer that adheres to these standards, you can ensure that your custom tubing will not only fulfill the project specifications but also exhibit durability and performance suited to the intended application. Ultimately, placing emphasis on the right manufacturer lays the foundation for successful project outcomes and long-term partnerships in the manufacturing industry.

Exploring Cost vs. Value in Custom Tubing Options

When selecting custom tubing for your project, understanding the balance between cost and value is crucial. While it may be tempting to choose the least expensive option, this can often lead to compromises in quality, performance, and durability. The initial savings may quickly be overshadowed by additional costs arising from failures, repairs, or replacements. Investing in higher-quality tubing may present a higher upfront cost, but it often pays off in the long run through enhanced reliability and reduced maintenance needs.

Moreover, value is not solely defined by monetary cost. Consideration of the specific requirements of your project—such as physical properties, intended use, and environmental conditions—plays a significant role in determining what constitutes a valuable option. For instance, selecting custom tubing specifically designed for high-pressure applications or harsh environments can offer a substantial advantage, ensuring safety and top-tier performance. Therefore, a thorough analysis of both cost and overall value leads to a more informed decision, ensuring that the chosen custom tubing not only fits the budget but also meets the project’s functional and lifespan expectations.

Related Posts

-

Top 10 Benefits of Using Plastic Channel in Your Projects

-

2025 Top 5 PVC Extrusion Profiles for Durable and Versatile Applications

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions

-

10 Essential Tips for Optimizing Plastic Extrusion Profiles and Enhancing Production Efficiency

-

How to Choose the Best Polycarbonate Tube for Your DIY Projects and Home Improvements

-

Exploring the Versatility of Polycarbonate Tubes: Innovations in Design and Application