How to Choose the Right PVC Extrusion Profiles for Your Project

Selecting the right PVC extrusion profiles for your project is a critical step that can significantly influence the overall success and functionality of your application. PVC, or polyvinyl chloride, is widely recognized for its versatility, durability, and cost-effectiveness, making it a preferred material in various industries. However, with the extensive range of PVC extrusion profiles available, the decision can often be daunting. Understanding the specific requirements of your project, such as load-bearing capacity, environmental exposure, and aesthetic appeal, is essential in making an informed choice.

In this guide, we will explore key considerations when choosing PVC extrusion profiles, emphasizing the importance of aligning your selection with project specifications. Factors such as profile geometry, customizability, and compatibility with other materials will be discussed to assist you in narrowing down your options. By the end of this discussion, you will understand the critical elements that should guide your selection of PVC extrusion profiles, ensuring that your project meets both performance standards and design expectations.

Understanding PVC Extrusion Profiles and Their Applications

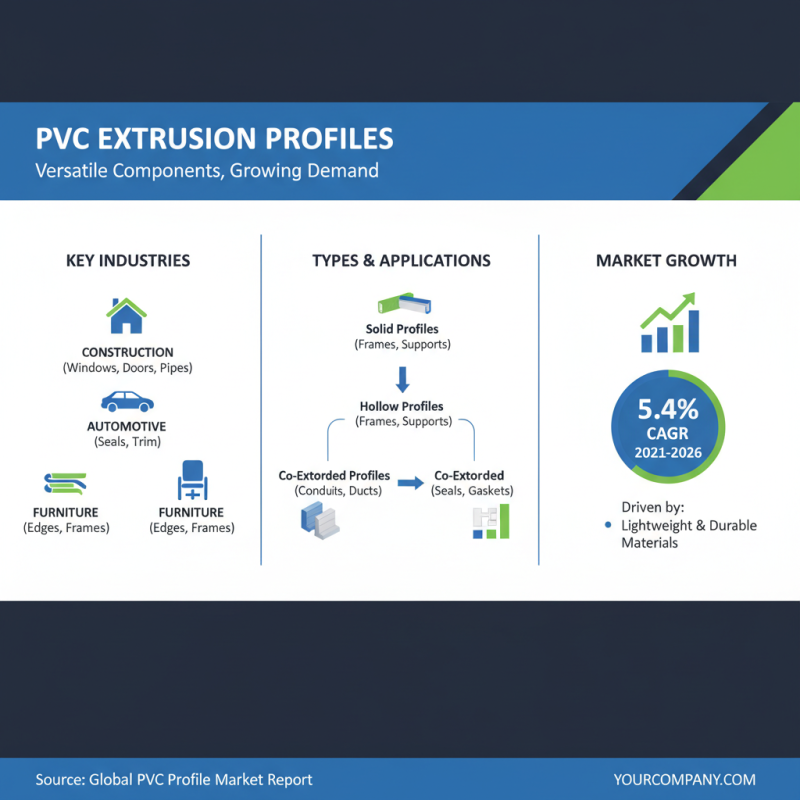

PVC extrusion profiles are versatile components widely utilized across various industries, including construction, automotive, and furniture manufacturing. Understanding the various types of PVC extrusion profiles and their specific applications is crucial for selecting the right profiles for your project. According to a recent report by the Global PVC Profile Market, the demand for PVC profiles is expected to grow at a CAGR of 5.4% from 2021 to 2026. This growth is driven by the increasing use of lightweight and durable materials in construction and design.

Different profiles, such as hollow and solid sections, serve distinct purposes. For instance, hollow profiles are often employed in window frames and doors due to their excellent insulation properties, while solid profiles are preferred in heavy-duty applications where structural strength is essential. Understanding these distinctions allows project managers to make informed decisions that align with both functional requirements and budget considerations.

Tip: Always assess the environmental conditions your profiles will face. For outdoor applications, consider UV-resistant profiles that prevent degradation over time. Another tip is to consult with manufacturers regarding the specifications and compliance standards they follow for their PVC materials, ensuring that you select profiles that meet industry regulations and performance expectations.

Factors to Consider When Choosing PVC Extrusion Profiles

Choosing the right PVC extrusion profiles for your project involves careful consideration of several key factors. First and foremost, you should evaluate the specific application and performance requirements. Different projects may demand varying levels of durability, flexibility, and resistance to environmental factors such as moisture, UV exposure, or chemicals. Ensure that the PVC profiles you select can withstand the operational environment while meeting aesthetic and functional needs.

Another critical factor is the dimensional specifications of the profiles. Precise measurements are essential to ensure proper fit and compatibility with other components. Examine the thickness, width, and length of the profiles to ensure they align with your design plans. Additionally, the manufacturing process can affect the quality and consistency of the profiles. It's important to choose materials that are produced under stringent quality control measures to guarantee uniformity and reliability in your final product. Taking these considerations into account will help you make informed decisions and ultimately lead to the success of your project.

Factors to Consider When Choosing PVC Extrusion Profiles

Evaluating the Physical Properties of PVC Materials

When selecting the appropriate PVC extrusion profiles for your project, evaluating the physical properties of PVC materials is crucial. PVC, or polyvinyl chloride, exhibits a variety of characteristics that influence its suitability for different applications. Key properties to consider include tensile strength, impact resistance, chemical stability, and thermal properties.

The tensile strength of PVC determines its ability to withstand force without breaking, making it suitable for structural applications. Similarly, impact resistance is essential for applications where the material may be subjected to shocks or collisions.

Another critical factor is the chemical stability of PVC, which affects its performance in various environments. Different PVC formulations provide varying levels of resistance to environmental factors like UV exposure, humidity, and temperature fluctuations. Understanding these properties helps in selecting the right PVC profile that will not degrade over time. Additionally, thermal properties such as heat distortion temperature need to be evaluated to ensure that the profiles can maintain their shape under operational conditions. By thoroughly assessing these physical properties, you can make informed choices that align with the specific demands of your project.

Matching PVC Profiles to Project Specifications and Requirements

When selecting the right PVC extrusion profiles for your project, it is essential to align your choice with the specific project specifications and requirements. The first step is to thoroughly understand the application of the profiles, including the environmental conditions they will face. For instance, profiles used in outdoor applications may need enhanced UV resistance and weatherproofing capabilities, while those intended for interior use might focus more on aesthetic appeal and structural integrity. Gathering detailed information about dimensions, load-bearing capacities, and thermal performance is crucial in ensuring that the selected profiles meet the demands of the project.

Furthermore, compatibility with other materials is another critical consideration. When integrating PVC profiles with metals, glass, or wood, it's vital to assess the potential for expansion, contraction, and overall interaction between materials. This compatibility directly impacts the durability and efficiency of the overall construction. Additionally, ensuring that the profiles can be easily fabricated and installed according to project timelines can significantly affect the project's success. By closely matching the profiles to these essential specifications and requirements, you can create a seamless and effective solution for your project's needs.

How to Choose the Right PVC Extrusion Profiles for Your Project

| Profile Type | Application | Material Thickness (mm) | Color Options | Finish Type | Weather Resistance |

|---|---|---|---|---|---|

| Standard Profile | Window Frames | 3.0 | White, Cream | Smooth | High |

| Decorative Profile | Interior Trim | 2.5 | Brown, Black | Textured | Medium |

| Heavy-Duty Profile | Commercial Doors | 4.0 | Gray, White | Glossy | Very High |

| Custom Profile | Unique Projects | Variable | Custom Colors | Varies | Depends on Spec |

Sourcing Quality PVC Extrusion Profiles from Reputable Suppliers

Sourcing quality PVC extrusion profiles is a crucial step for any project that requires durable and versatile materials. When looking for reputable suppliers, focus on their track record and customer reviews to gauge their reliability. A supplier with a proven history in delivering high-quality products can save you time and money in the long run, ensuring that your project meets the desired standards without unnecessary delays.

Tip: Always request samples from potential suppliers before making a bulk purchase. This will allow you to assess the quality of their PVC extrusion profiles firsthand. Check for consistency in width, thickness, and overall finish, as these factors can significantly impact the performance of your final product.

Another important aspect is to inquire about the suppliers' manufacturing processes. Quality extrusion profiles should undergo rigorous testing and quality control measures. Understanding their production methodology will give you insight into their commitment to quality and help you make an informed decision.

Tip: Look for suppliers who are willing to provide certifications or documentation regarding their materials and processes. This transparency not only builds trust but also assures you of the quality and compliance of your materials with industry standards. By taking these steps, you'll be better positioned to select the right PVC extrusion profiles for your project.

Related Posts

-

2025 Top 5 PVC Extrusion Profiles for Durable and Versatile Applications

-

Understanding the Role of PVC Extrusions in Sustainable Building Designs

-

Top 5 Benefits of PVC Extrusions for Modern Construction and Design

-

2025 Ultimate Guide to Choosing the Best Plastic Profiles for Your Projects

-

Innovative Ways to Use Layflat Polythene Tubing in Your Next Project

-

Exploring the Benefits of Plastic Hinges: Durability and Cost-Efficiency in Modern Applications