How to Choose the Right Hard Plastic Tubing for Your Project Needs

When it comes to selecting the appropriate hard plastic tubing for your project, understanding the specific requirements of your application is crucial. Industry expert Dr. Emily Thompson, a leading authority in polymer materials, emphasizes that "the choice of hard plastic tubing can significantly influence the durability and efficiency of the entire system." As various projects demand different properties, such as temperature resistance, chemical compatibility, and pressure ratings, making an informed decision is essential to achieve optimal results.

Choosing the right hard plastic tubing involves several key considerations, including material type, diameter, and wall thickness. Each of these factors plays a vital role in the performance of the tubing under specific operational conditions. For instance, polycarbonate and PVC are common materials used for hard plastic tubing, each offering distinct advantages depending on the intended use. Moreover, proper sizing can aid in preventing leaks and ensuring that the tubing can withstand the pressures it will encounter.

In summary, the right hard plastic tubing is not just a functional component; it is a critical element that can enhance the overall success of your project. Therefore, taking the time to evaluate your options carefully can lead to significant long-term benefits, both in the performance and reliability of your installation.

Understanding the Different Types of Hard Plastic Tubing Available

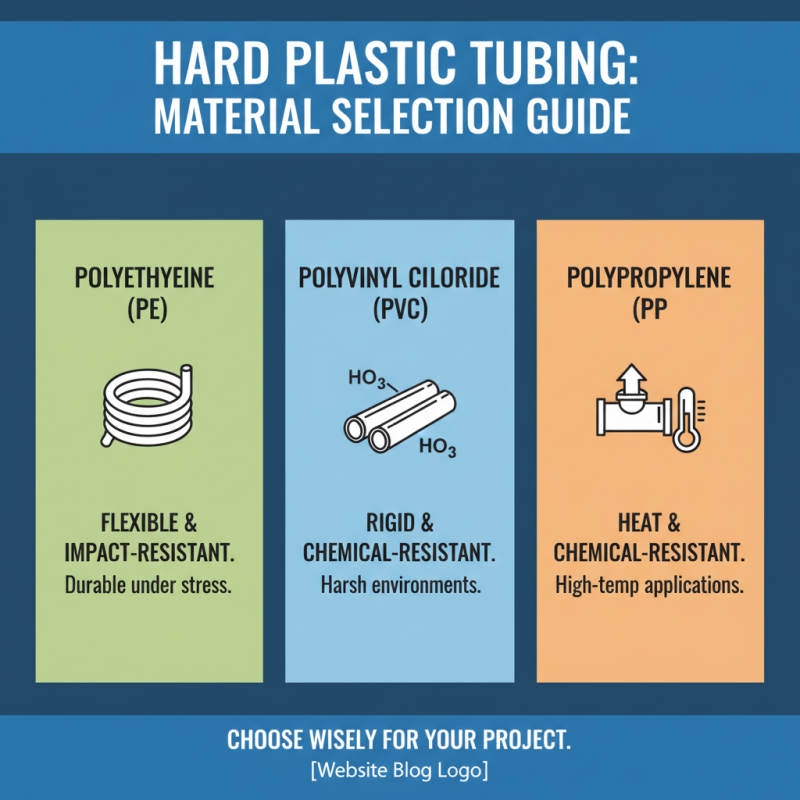

When selecting hard plastic tubing for your project needs, it's essential to understand the various types available in the market. Hard plastic tubing can be made from materials such as polyvinyl chloride (PVC), polyethylene (PE), and acrylonitrile butadiene styrene (ABS), each possessing distinct properties that make them suitable for different applications. According to a report from the Plastic Pipe and Fittings Association (PPFA), the global plastic pipe market was valued at approximately $50 billion in 2021, with projections indicating a compound annual growth rate (CAGR) of around 3.5% from 2022 to 2027. This growth reflects the increasing reliance on plastic tubing in various industries, including construction, agriculture, and automotive manufacturing.

PVC tubing is renowned for its versatility, making it ideal for plumbing and electrical wiring applications due to its resistance to moisture and chemicals. Conversely, polyethylene tubing is flexible and resistant to impact, making it a popular choice for fluid transport in agricultural settings. ABS, known for its strength and durability, is frequently utilized in heavy-duty applications, including venting and drainage systems. Understanding these material differences, along with factors such as temperature resistance and pressure ratings, is crucial when deciding on the appropriate hard plastic tubing for specific projects. The ability to match the right tubing with project requirements can significantly enhance performance and longevity while reducing the likelihood of costly repairs or failures.

Comparison of Different Types of Hard Plastic Tubing

Key Factors to Consider When Selecting Hard Plastic Tubing

When selecting hard plastic tubing for your project, several key factors should be carefully considered to ensure optimal performance and compatibility with your specific needs. One of the primary considerations is the material composition of the tubing. Common materials include polyvinyl chloride (PVC), polypropylene (PP), and polycarbonate (PC), each offering different properties such as chemical resistance, temperature tolerance, and flexibility.

According to a report by the Plastics Industry Association, PVC has a robust market presence due to its versatility, holding approximately 25% of the total plastic resin consumption in North America in 2022.

Another crucial factor is the tubing's mechanical properties, which include tensile strength, impact resistance, and rigidity. For instance, polycarbonate tubing is known for its high impact resistance and is often used in applications where durability is paramount. A study by Market Research Future forecasts the hard plastic tubing market to grow at a CAGR of 4.5% from 2021 to 2028, emphasizing the increasing demand for high-performance materials across diverse industries such as automotive and construction. Understanding these mechanical properties will guide manufacturers and engineers in selecting tubing that performs reliably under the expected conditions.

Finally, the dimensions and specifications of the tubing, including diameter, wall thickness, and length, play a significant role in ensuring compatibility with existing systems. It’s essential to assess the specific requirements of your project, including flow rates and pressure levels, to select tubing that aligns with operational demands. Data from the American Society for Testing and Materials (ASTM) indicates that improper sizing can lead to failures or inefficiencies, highlighting the importance of precision in the selection process.

Analyzing the Durability and Resistance of Various Tubing Materials

When choosing hard plastic tubing for your project, understanding the durability and resistance of various materials is crucial. Different types of plastic, such as polyethylene, polyvinyl chloride (PVC), and polypropylene, offer distinct qualities that cater to specific applications. For instance, polyethylene is known for its flexibility and resistance to impact, making it suitable for applications requiring durability under stress. Conversely, PVC, while less flexible, provides excellent chemical resistance, making it ideal for installations in environments where exposure to harsh substances is anticipated.

Additionally, it is essential to consider the temperature resistance of the tubing material. Some plastics can withstand higher temperatures without deforming, while others may become brittle in cold conditions. Therefore, if your project involves exposure to temperature fluctuations, selecting a material with appropriate thermal resistance is critical. Overall, evaluating the specific conditions your tubing will face—such as chemical exposure, temperature variations, and physical stresses—will help you select the right hard plastic tubing that meets your project's requirements effectively.

Determining the Appropriate Size and Dimensions for Your Project

When selecting hard plastic tubing for your project, determining the appropriate size and dimensions is crucial to ensure functionality and compatibility within the intended application. According to industry standards, such as those established by ASTM International, proper sizing can influence factors like flow rate, pressure resistance, and structural integrity.

For example, using tubing with an internal diameter that is too small can restrict fluid flow and lead to increased pressure buildup, which may ultimately compromise the system and result in failures.

Another important aspect involves understanding the wall thickness and material properties of the tubing. The Plastics Pipe Institute reports that the wall thickness directly impacts the tubing's strength and flexibility. The thicker walls provide greater strength and resistance to external pressure, making them suitable for high-stress environments. Meanwhile, diverse applications, ranging from industrial to residential use, necessitate careful consideration of size metrics, with many engineers relying on empirical data to determine the optimal dimensions.

By precisely evaluating these factors, one can select hard plastic tubing that meets both project specifications and performance expectations effectively.

Applications of Hard Plastic Tubing in Various Industries and Projects

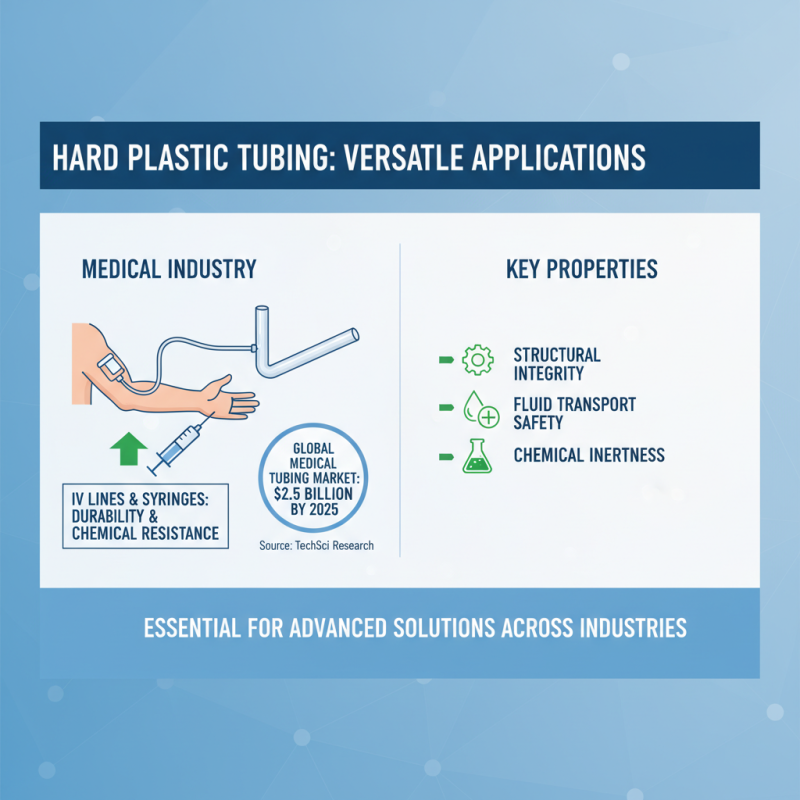

Hard plastic tubing is a versatile solution used across various industries, each leveraging its unique properties for specific applications. In the medical industry, for instance, hard plastic tubing is crucial in the design of devices such as IV lines and syringes, where durability and resistance to chemicals are key factors. A report by TechSci Research indicates that the global plastic medical tubing market is expected to reach USD 2.5 billion by 2025, driven by the growing demand for advanced healthcare solutions. The ability of hard plastic tubing to maintain its structure under pressure makes it ideal for transporting fluids safely in these environments.

In construction and plumbing, hard plastic tubing is utilized for both water supply and drainage systems, owing to its lightweight yet sturdy nature. According to a study by MarketsandMarkets, the global plastic pipe market size was valued at USD 163.5 billion in 2019 and is projected to reach USD 206.7 billion by 2025, with a significant portion attributed to the adoption of hard plastic tubing in residential and commercial projects. Its resistance to corrosion, ease of installation, and longevity ensure that hard plastic tubing plays a vital role in modern infrastructure development, addressing both efficiency and cost-effectiveness.

Related Posts

-

Top Uses for Clear Plastic Tubes in 2025 and Innovative Ideas You Need to Know

-

How to Choose the Best Flexible Plastic Tubing for Your Needs

-

Top Trends in Rigid Plastic Tubing for 2025 What You Need to Know

-

How to Choose the Right Plastic Channel for Your Wiring Needs

-

2025 Top Uses for Layflat Polythene Tubing in Various Industries

-

Top 10 Tips for Choosing the Right Custom Tubing for Your Project