Why You Should Choose Plastic Channels for Your Next Project

In the ever-evolving landscape of construction and design, the choice of materials can significantly impact both functionality and sustainability. One material that has gained remarkable traction is the plastic channel. Renowned industry expert Dr. Emily Carter, a leading authority in building materials, emphasizes the benefits of this versatile solution by stating, "Plastic channels not only enhance the efficiency of projects but also offer unmatched durability and resistance to environmental factors."

As architects and builders increasingly seek innovative solutions that align with eco-friendly practices, plastic channels emerge as a compelling option. They are lightweight, easy to install, and can be customized to fit various specifications, making them ideal for a wide range of applications. With the growing demand for sustainable alternatives, incorporating plastic channels can significantly reduce the carbon footprint of any project.

Ultimately, choosing plastic channels for your next project can lead to enhanced performance and longevity, while contributing to a greener future. With insights from experts like Dr. Carter, it becomes clear that this material is not just a passing trend but a strategic choice for contemporary construction challenges.

Benefits of Using Plastic Channels Over Other Materials

When considering materials for your next project, plastic channels offer distinct advantages over traditional options like metal or wood. One major benefit is their resistance to corrosion and moisture, making them ideal for outdoor or humid environments where durability is crucial. Unlike metal, plastic does not rust or degrade, ensuring a longer lifespan and lower maintenance costs.

Another key advantage is the lightweight nature of plastic channels. This makes them easier to handle during installation, which can significantly reduce labor costs. Additionally, plastic channels are easy to cut and shape, allowing for greater flexibility in design. This adaptability makes them a preferred choice for both construction and creative projects.

Tips: When selecting plastic channels, consider the specific environmental conditions they will face. Using UV-resistant materials can further enhance durability in sunny locations. Additionally, always double-check the size and dimensions to ensure a perfect fit for your project requirements. By planning ahead, you can leverage the full benefits of plastic channels and achieve a successful outcome for your project.

Durability and Longevity of Plastic Channels in Various Environments

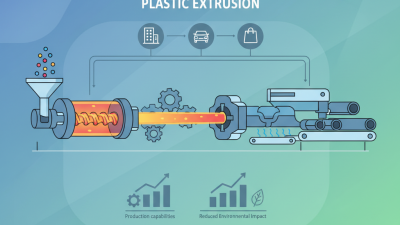

Plastic channels are increasingly gaining popularity across various industries due to their remarkable durability and longevity in diverse environments. Research shows that plastic channels can withstand a wide range of temperatures, from -40°F to 140°F, making them suitable for both extreme cold and heat applications. This resilience is often supported by a production process that enhances the molecular structure of plastics, allowing them to resist cracking, warping, and corrosion. According to a study published by the American Society for Testing and Materials (ASTM), the lifespan of high-quality plastic channels in outdoor settings can exceed 50 years, significantly reducing the need for replacements and repairs compared to traditional materials such as metal or wood.

Moreover, plastic channels can effectively endure exposure to chemicals and harsh conditions, which is vital in industrial settings. A report from the Plastics Industry Association indicates that plastic materials can resist a variety of acids and bases, making plastic channels ideal for environments such as chemical processing plants and wastewater treatment facilities. The functionality is not compromised by UV exposure either; modern formulations include additives that protect against sun damage, further extending their life and maintaining structural integrity. This combination of durability and longevity makes plastic channels an exceptional choice for a wide range of projects, ensuring long-term performance without sacrificing quality.

Cost-Effectiveness of Plastic Channels for Budget-Conscious Projects

When considering cost-effective solutions for projects, plastic channels emerge as a compelling option. According to recent industry reports, plastic channels can be up to 30% cheaper than their metal counterparts, primarily due to lower material costs and simplified installation processes. This affordability makes them especially attractive for budget-conscious projects where maximizing resources is essential. Additionally, plastic channels are lightweight, which reduces shipping costs and labor expenses during installation, further enhancing their budget-friendly appeal.

Tips: To ensure you make the most out of your investment, choose high-quality plastic channels that offer durability. Look for products with UV protection and impact resistance, as these features will extend the lifespan of your channels, leading to long-term savings.

Moreover, with their excellent resistance to corrosion and chemicals, plastic channels require less maintenance over time, which translates into reduced operational costs. A study from the American Society for Testing and Materials reveals that projects utilizing durable plastic solutions report a significant drop in repair and replacement expenses, allowing funds to be allocated to other critical areas of development.

Tips: Before finalizing your decision, conduct a cost-benefit analysis comparing initial costs against potential long-term savings. This approach will help ensure you select the most economically viable option for your project's specific needs.

Why You Should Choose Plastic Channels for Your Next Project - Cost-Effectiveness of Plastic Channels for Budget-Conscious Projects

| Dimension | Plastic Channel Type | Cost per Meter (USD) | Weight (kg/m) | Durability (Years) |

|---|---|---|---|---|

| 50mm x 50mm | Standard Plastic | $2.50 | 0.5 | 10 |

| 75mm x 75mm | Heavy-Duty Plastic | $4.00 | 0.8 | 15 |

| 100mm x 100mm | UV-Resistant Plastic | $5.00 | 1.0 | 20 |

| 30mm x 30mm | Lightweight Plastic | $1.80 | 0.3 | 8 |

Environmental Considerations: Recyclability and Sustainability of Plastics

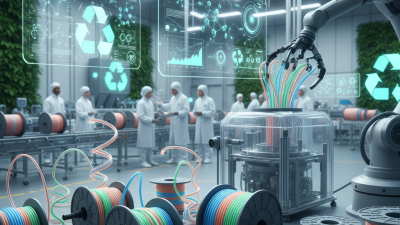

When considering materials for your next project, the environmental impact should play a pivotal role in your decision. Plastic channels present a compelling choice, particularly due to their recyclability and sustainability. Unlike many traditional materials, plastics can be recycled multiple times without losing their quality or utility. This makes them an attractive option for projects looking to minimize waste and environmental footprint. Many manufacturers now offer plastic channels made from post-consumer recycled materials, contributing to a circular economy.

The sustainability of plastics also extends beyond their recyclability. Innovations in the plastics industry have led to the development of biodegradable variants and bio-based plastics derived from renewable resources. These advancements not only help mitigate the reliance on fossil fuels but also lessen the carbon footprint associated with production. By selecting plastic channels, you are not only integrating a versatile and durable material into your project but also supporting the broader movement towards environmentally responsible construction practices. This makes a strong case for choosing plastics as a viable, eco-friendly option for your future endeavors.

Versatility of Plastic Channels in Different Applications and Industries

Plastic channels are becoming an increasingly popular choice across various industries due to their remarkable versatility. In construction, for instance, they are widely used for cable management, ensuring organized and secure routing of electrical wires. Their lightweight nature simplifies installation, while their resistance to moisture and chemicals makes them ideal for environments where exposure to harsh conditions is a concern. This adaptability not only enhances safety but also contributes to the longevity of installations.

In the manufacturing sector, plastic channels serve multiple purposes, including conveyor systems and product sorting. Their ability to be easily molded into different shapes allows for customized solutions that fit specific operational needs. Furthermore, the use of plastic channels promotes efficiency by reducing friction and wear, leading to longer-lasting equipment and reduced maintenance costs. From food processing to electronic assembly lines, the applications of plastic channels are vast, offering reliable and practical solutions that cater to the diverse requirements of modern industries.

Versatility of Plastic Channels in Different Applications

Related Posts

-

How to Choose the Right Plastic Channel for Your Wiring Needs

-

Top 10 Benefits of Using Plastic Channel in Your Projects

-

What is a Plastic Extruder and How Does it Work in Manufacturing Processes

-

10 Best Uses for Clear Plastic Tubes in Your Projects and Crafts

-

2025 Top 5 Frosted Acrylic Tube Products You Need to Know

-

2025 Top Trends in Flexible Plastic Tubing: Innovations and Applications