How to Choose the Best Flexible Plastic Tubing for Your Needs

Flexible plastic tubing plays a pivotal role in a variety of industries, including medical, food and beverage, automotive, and pharmaceuticals. According to a recent report by MarketsandMarkets, the flexible plastic tubing market is projected to reach USD 18.5 billion by 2025, growing at a CAGR of 5.2% from 2020. This significant growth underscores the increasing demand for versatile and durable tubing solutions that address specific application requirements across these sectors.

As industries evolve, the need for customized solutions continues to rise. Selecting the best flexible plastic tubing involves considering factors such as material compatibility, temperature resistance, and pressure ratings. A study published in the Journal of Polymer Science highlights the importance of material properties in ensuring the safety and efficacy of applications, particularly in the medical field where regulatory compliance is paramount. With a myriad of options available, understanding the nuances of flexible plastic tubing is crucial for professionals aiming to optimize their operations and meet stringent industry standards.

Hence, making informed decisions when choosing flexible plastic tubing can lead to improved efficiency, safety, and overall performance in various applications. By leveraging data and insights from industry reports, engineers and procurement specialists can better navigate the complexities of tubing selection to suit their unique operational needs.

Understanding the Types of Flexible Plastic Tubing Available

When selecting flexible plastic tubing, it's essential to understand the various types available to ensure you choose the best one for your specific application. Common types include PVC, polyethylene, and nylon. PVC tubing is versatile and widely used due to its durability and resistance to chemicals, making it ideal for both commercial and residential purposes. Polyethylene tubing, on the other hand, offers excellent flexibility and is often chosen for lightweight applications such as water lines or irrigation systems. Its resistance to stress cracking further enhances its appeal for those seeking a reliable solution.

Another popular option is nylon tubing, known for its strength and high-temperature resistance. This type is frequently utilized in more demanding environments, such as automotive and industrial applications, where durability is crucial. Often, nylon tubing remains flexible even in cold conditions, making it suitable for a variety of climates. Understanding these types of flexible plastic tubing can help you make an informed choice based on factors like temperature range, chemical exposure, and the specific needs of your project.

Evaluating Material Properties for Your Specific Application

When selecting flexible plastic tubing for specific applications, it is essential to thoroughly evaluate the material properties that will impact performance and suitability. Key factors to consider include chemical resistance, temperature tolerance, and flexibility. For instance, if the tubing will be exposed to harsh chemicals, choosing a material with high chemical resistance is crucial to ensure durability and prevent degradation. Likewise, understanding the operating temperature range is vital, as some plastics may lose their integrity or flexibility when subjected to extreme heat or cold.

Another important aspect to consider is the tubing's flexibility and wall thickness. The intended application often dictates how flexible the tubing needs to be; for instance, in tight spaces or complex routing scenarios, more flexible options are preferable. In contrast, applications requiring higher pressure might benefit from thicker walls to withstand stress without compromising integrity. Additionally, factors like permeation, bio-compatibility, and environmental considerations should also play a role in the selection process, as these can significantly influence the long-term effectiveness and safety of the tubing in its intended use.

Choosing the Best Flexible Plastic Tubing: Material Properties Comparison

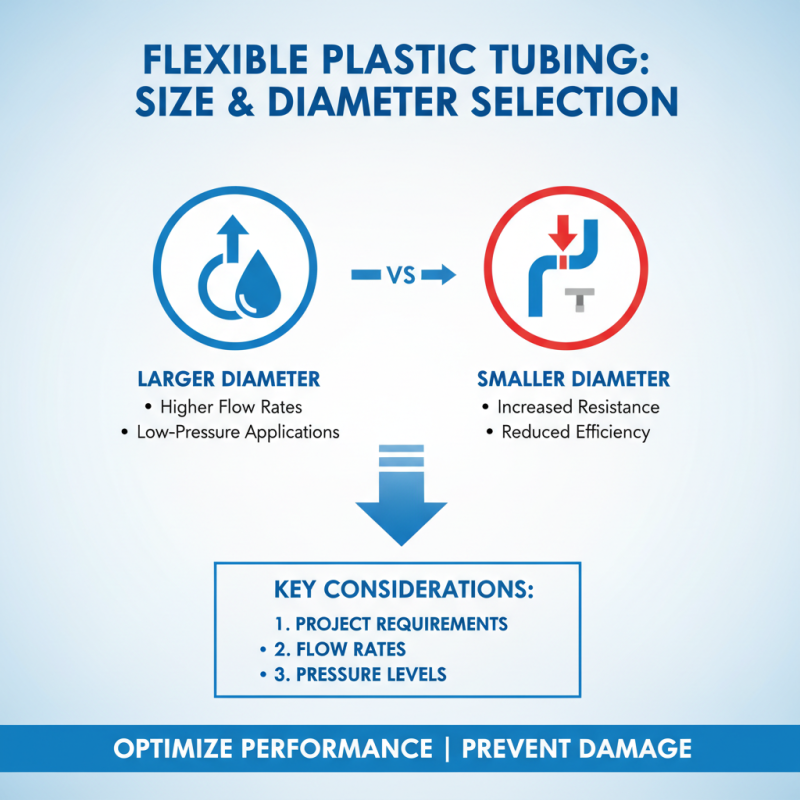

Key Factors to Consider When Selecting Tubing Size and Diameter

When selecting flexible plastic tubing, size and diameter are critical factors that directly impact the tubing's performance in various applications. First, it is essential to understand the specific requirements of the project or system in which the tubing will be utilized. Consider the flow rates and pressure levels required; larger diameters generally allow for higher flow rates but may be unnecessary for low-pressure applications. Conversely, using tubing that is too small can lead to constriction and increased resistance, thereby reducing efficiency and potentially causing damage to the system components.

Another important aspect to consider is the material's compatibility with the media being transported. Different materials can exhibit varying levels of resistance to chemicals and temperature fluctuations. Ensuring that the tube's diameter aligns with the specific environmental conditions and types of fluids will help prevent issues such as leaks or degradation of the material. Additionally, potential installation space limitations should also guide the choice of size, as the tubing must fit appropriately within the designated area while allowing for ease of handling and routing.

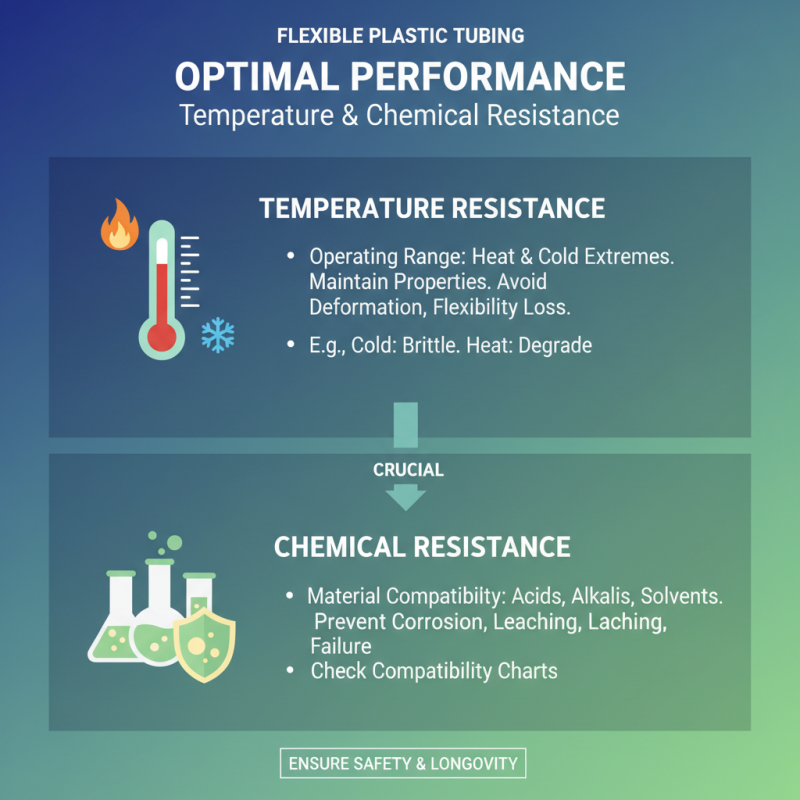

Assessing Temperature and Chemical Resistance in Tubing Options

When selecting flexible plastic tubing, understanding its temperature and chemical resistance is crucial for ensuring optimal performance in various applications. Temperature resistance refers to the ability of the tubing material to maintain its physical and chemical properties under extremes of heat or cold. It's essential to evaluate the operating temperature range specified for the tubing, as exceeding it can lead to deformation, loss of flexibility, and compromised safety. For instance, some materials may be ideal for colder environments but may become brittle at high temperatures, while others can handle significant heat but might degrade in lower temperatures.

Chemical resistance is equally important, as different tubing materials interact uniquely with various substances, including acids, bases, and solvents. This interaction can result in swelling, cracking, or complete failure of the tubing. To make an informed choice, it's essential to review compatibility charts specific to the tubing types being considered. Factors such as the concentration of chemicals, exposure duration, and environmental conditions also play a role in determining the tubing's longevity and effectiveness. By thoroughly assessing these parameters, users can select the most suitable flexible plastic tubing for their specific needs, ensuring durability and reliability in their applications.

Exploring Cost-Effectiveness and Availability of Flexible Tubing Choices

When choosing flexible plastic tubing, it's imperative to consider cost-effectiveness and the availability of various options in the marketplace. According to a recent report by MarketsandMarkets, the global market for flexible plastic tubing is projected to grow from USD 2.8 billion in 2022 to USD 4.1 billion by 2027, at a CAGR of 8.5%. This growth is driven by diverse applications in industries such as healthcare, food and beverage, and chemical processing. The rising demand for lightweight and durable materials makes flexible plastic tubing a popular choice, offering an ideal solution for efficient transportation of fluids, gases, and granular substances.

Cost-effectiveness is often a determining factor in selecting the right tubing. Flexible plastic options typically provide a lower initial investment compared to alternatives like metal or rigid plastic, while also ensuring durability that can lead to long-term savings. The North American plastic tubing market alone accounts for a significant share, owing to the increasing adoption of flexible solutions in manufacturing and construction sectors. Additionally, the availability of options made from various materials, such as PVC, polyurethane, and silicone, allows for tailored choices that meet specific regulatory and functional requirements without compromising affordability. An industry analysis indicates that PVC remains the most commonly used material, primarily due to its balance of robustness and cost efficiency.

How to Choose the Best Flexible Plastic Tubing for Your Needs

| Type of Tubing | Material | Cost per Meter | Temperature Range (°C) | Availability |

|---|---|---|---|---|

| PVC Tubing | Polyvinyl Chloride | $0.50 | -10 to 60 | Widely Available |

| Polyurethane Tubing | Polyurethane | $0.80 | -40 to 80 | Commonly Available |

| Silicone Tubing | Silicone | $1.50 | -60 to 200 | Readily Available |

| Nylon Tubing | Nylon | $1.20 | -40 to 100 | Available |

| Tygon Tubing | Tygon | $2.00 | -30 to 70 | Limited Availability |

Related Posts

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions

-

Top Uses for Clear Plastic Tubes in 2025 and Innovative Ideas You Need to Know

-

2025 Top Trends in Flexible Plastic Tubing: Innovations and Applications

-

How to Choose the Best Polycarbonate Tube for Your DIY Projects and Home Improvements

-

What is a Plastic Extruder and How Does it Work in Manufacturing Processes

-

Understanding the Role of PVC Extrusions in Sustainable Building Designs