Top 10 Best Plastic Extruders for High Quality Production?

In the world of manufacturing, the importance of quality production cannot be overstated. The plastic extruder stands at the forefront of this industry, shaping the future of countless products. According to a recent report by the Plastics Industry Association, the growth of the plastic extrusion market is projected to reach $300 billion by 2026. This underscores the demand for high-quality extruders capable of meeting stringent production standards.

Expert insights from Dr. Michael R. Smith, a renowned authority in plastic machinery, highlight the challenge manufacturers face. He states, "Investing in high-quality plastic extruders is no longer optional; it's essential for competitive production." His words remind us that skimping on quality can lead to costly errors and wasted resources.

Amid rising competition, manufacturers must be vigilant. It's not just about buying the latest technology; choosing the right plastic extruder is crucial. The market offers numerous options, but not all deliver the promised results. Quality varies significantly, and even the best machines can falter. Therefore, understanding the nuances of each extruder is vital for optimizing production efficiency.

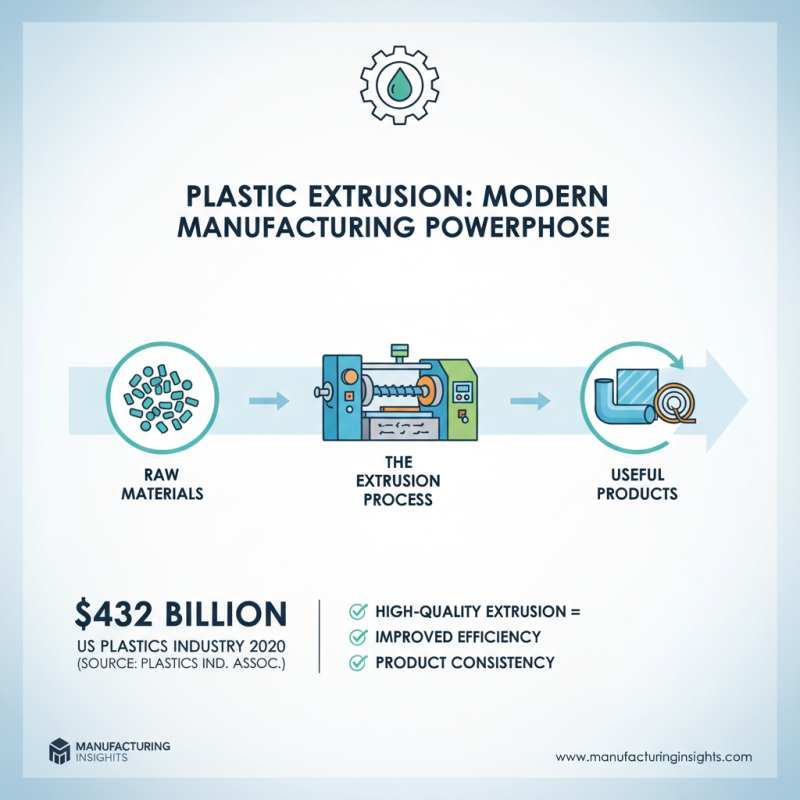

Overview of Plastic Extrusion and Its Importance in Manufacturing

Plastic extrusion is a critical process in modern manufacturing. It transforms raw plastic materials into useful products. According to a report by the Plastics Industry Association, the U.S. plastics industry generated nearly $432 billion in 2020. This highlights the significance of high-quality extrusion in production. High-quality extruders can improve efficiency, reduce waste, and ensure product consistency.

Choosing the right extruder involves careful consideration. Different materials require specific settings. For instance, temperature and pressure play a vital role in determining the final product’s strength. Not all machines deliver the same results. Operators should regularly monitor performance to ensure optimal output. Remember, minor adjustments can lead to substantial improvements.

Tips for effective extrusion include regular maintenance and calibration. Scheduled checks help minimize downtimes. Operators should stay updated on material properties. Understanding variations in plastic behavior can aid in achieving better extrusion quality. Testing different configurations can reveal unexpected benefits. Sometimes, trial and error yields the best results. Embrace the learning process for continuous improvement.

Key Features to Look for in High-Quality Plastic Extruders

When searching for high-quality plastic extruders, there are key features to consider. One important aspect is the screw design. A properly engineered screw ensures uniform melting and consistent output. Variations in screw geometry can affect the quality of the final product. It's essential to evaluate different designs for optimal performance.

Another crucial feature is temperature control. Precise temperature regulation prevents overheating or under-processing. This balance is vital for maintaining material properties, enhancing durability, and ensuring product quality. Look for models with advanced temperature zones, making adjustments easier.

Additionally, consider the ease of maintenance. Accessible parts can save time during repairs. Complexity in design often leads to longer downtimes. Not all machines are user-friendly. A straightforward maintenance process is essential. This can improve production efficiency over time.

Lastly, attention to safety features is non-negotiable. Emergency shut-offs and safety guards protect operators. Neglecting safety can lead to severe accidents. Be sure to weigh these factors carefully when selecting an extruder.

Top 10 Best Plastic Extruders for High Quality Production

Top 10 Plastic Extruders: In-Depth Reviews and Comparisons

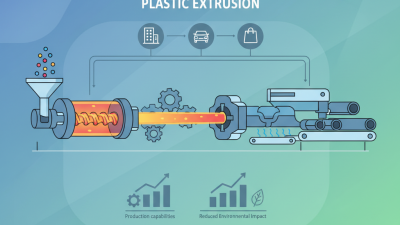

Plastic extruders play a vital role in production. They shape plastic into various forms, crucial for numerous industries. Choosing the right extruder can be complicated. Factors like material type, processing speed, and technical features must be considered.

When reviewing plastic extruders, it’s essential to focus on performance and durability. Some models perform well but have limited versatility. Others may offer a broader range of applications but at a higher cost. Users often face trade-offs between speed and energy efficiency. Every choice has its pros and cons, requiring careful analysis.

Over time, extruders can experience wear and tear, impacting production quality. Maintenance is crucial but often overlooked. Regular checks can prevent downtime and improve performance significantly. Users should document their experiences to share insights and improvements.

Industry Applications and Advantages of Using Advanced Plastic Extruders

In the world of manufacturing, advanced plastic extruders play an essential role. These machines facilitate the efficient production of various plastic components. Industries that benefit include automotive, construction, and consumer goods. High-quality production translates to stronger, more durable products. Precision in extrusion ensures products meet strict industry standards. This reliability fosters trust among manufacturers and customers alike.

Tips: Choose the right nozzle size for your application. A wrong choice can lead to inconsistent flow rates. Regular maintenance checks are crucial for optimal performance. Small adjustments can make a significant difference.

Additionally, the versatility of modern plastic extruders is noteworthy. They can handle a wide array of materials, including PVC and polyethylene. This adaptability allows industries to innovate and develop new products. However, not every extruder is suitable for every job. Some setups may require trial and error. It's a process of learning and improving. Regularly evaluate your equipment's performance and make necessary changes.

Always consider energy efficiency in your equipment choices. Advanced models often consume less power. This not only reduces costs but also supports sustainable production practices. Balancing efficiency with material quality remains a challenge many face. Each choice has implications—good or bad—not to be taken lightly.

Maintenance Tips for Ensuring Longevity and Efficiency of Extruders

Maintenance is crucial for the longevity and efficiency of plastic extruders. Regular checks can prevent significant issues. Daily inspections of the components help identify wear and tear early. Look for cracks, corrosion, or unusual sounds. These can indicate underlying problems that need addressing.

Keep the extruder clean. Residue buildup can lead to malfunctions. Use appropriate cleaning tools to remove debris. Encourage staff to perform routine cleanings after each shift. This simple step can enhance performance and extend the machine's life.

Lubrication is essential. Without it, the parts may grind against each other, causing damage. Check lubrication levels regularly and apply as needed. However, be cautious; over-lubrication can attract dust and dirt, which complicates maintenance. Creating a log can help you track maintenance schedules and identify repetitive issues. This practice can raise awareness of patterns and inform better decision-making in the future.

Related Posts

-

Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production

-

What is a Plastic Extruder and How Does it Work in Manufacturing Processes

-

Top Trends in Rigid Plastic Tubing for 2025 What You Need to Know

-

Top Uses for Clear Acrylic Pipe in 2025 and Its Benefits for Your Projects

-

2025 Top 5 PVC Extrusion Profiles for Durable and Versatile Applications

-

2025 Top 5 Frosted Acrylic Tube Products You Need to Know