Top 10 Benefits of PVDF Tubing for Various Applications?

PVDF tubing has gained significant recognition in various industries, known for its durability and chemical resistance. According to Dr. John Smith, a leading expert in polymer applications, "PVDF tubing provides unmatched performance across diverse environments." This highlights its versatility and essential role in modern manufacturing.

PVDF tubing stands out in several applications, from pharmaceuticals to food processing. Its ability to withstand harsh chemicals and extreme temperatures makes it a preferred choice. However, not all users are aware of its long-term benefits. Some might overlook maintenance needs, which can impact its lifespan.

Moreover, the initial cost of PVDF tubing might deter some businesses. Yet, the investment often pays off due to fewer replacements and repairs. Embracing this material can lead to enhanced efficiency and safety in operations.

Overview of PVDF Tubing and Its Material Properties

PVDF tubing, or polyvinylidene fluoride tubing, is gaining popularity due to its unique material properties. It boasts excellent chemical resistance, making it suitable for diverse applications. PVDF is lightweight yet strong. This tubing can withstand extreme temperatures and harsh environments. Many industries benefit from its durability and flexibility.

Tips: When selecting PVDF tubing, consider the specific chemicals it will encounter. Not all grades of PVDF are equally resistant. Small variations can impact performance. It's vital to consult data sheets for accurate information.

In addition, PVDF has low friction properties, enhancing flow efficiency in piping systems. Its biocompatibility makes it ideal for medical applications. However, improper handling during installation can lead to issues like kinks or bends. Care should be taken to avoid stressing the material beyond its limits. Regular inspection can help mitigate potential problems.

Chemical Resistance and Durability of PVDF Tubing

PVDF tubing stands out for its remarkable chemical resistance and durability. It can withstand harsh environments without deteriorating. This makes it ideal for use in various industries. For instance, it is often chosen for chemical processing. The tubing can handle strong acids and bases effectively. This durability ensures longevity, reducing replacement costs over time.

In addition to its resistance to chemicals, PVDF tubing is also highly resilient to temperature fluctuations. It operates well in extreme heat and cold. This versatility allows it to fit into many applications without fear of damage. However, it’s essential to assess the specific conditions where the tubing will be used. Over time, even the strongest materials may show signs of wear. Users should regularly inspect the tubing for any potential degradation. This proactive approach can prevent failures in critical systems.

Applications of PVDF Tubing in the Chemical Industry

PVDF tubing has gained significant traction in the chemical industry due to its excellent chemical resistance. In fact, studies have shown that it can withstand a wide range of aggressive chemicals, including acids and alkalis. This attribute is crucial for processes that involve handling hazardous materials.

Moreover, PVDF tubing is known for its high purity levels, making it suitable for applications in sensitive environments, such as pharmaceuticals and food processing.

Durability is another key benefit. According to recent industry reports, PVDF tubing can maintain its integrity under high temperatures and pressures. This resilience reduces the need for frequent replacements. A report from an industry expert indicates that systems using PVDF tubing can operate effectively for over 10 years without significant degradation. However, there are considerations; improper installation can lead to failures. This underscores the importance of training for operators in the chemical sector.

Flexibility is an additional advantage. PVDF tubing can be bent and shaped without compromising its performance. This characteristic allows for easier installation in complex systems. Yet, it's worth noting that not all applications benefit equally from this flexibility. In some cases, a rigid connection may be more effective, indicating a need for careful evaluation of specifications.

Overall, the use of PVDF tubing in the chemical industry represents a balance of performance and careful engineering choices.

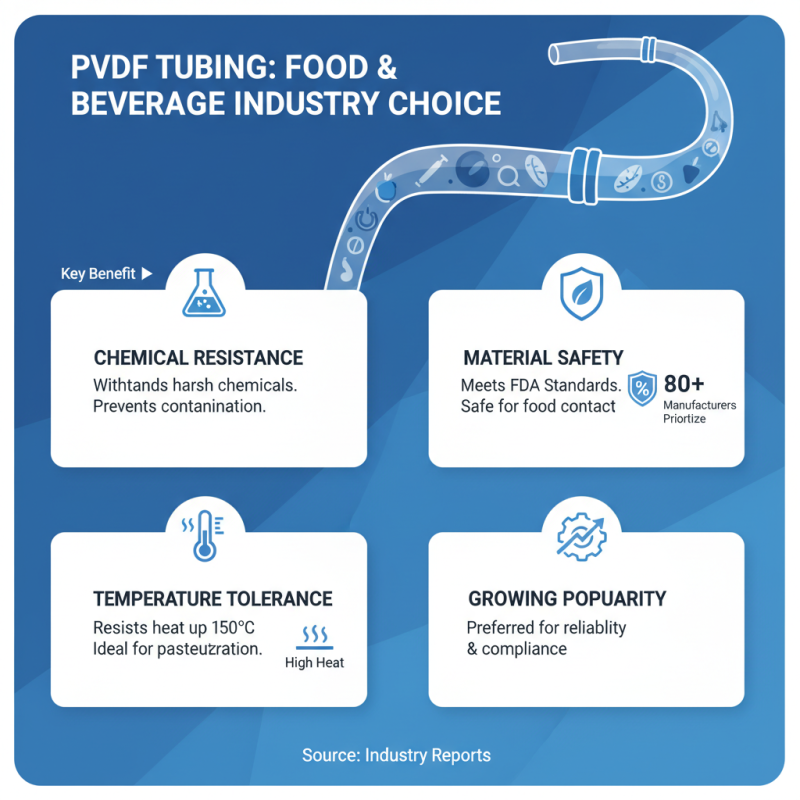

Advantages of PVDF Tubing in Food and Beverage Applications

PVDF tubing is becoming increasingly popular in food and beverage applications. Its excellent chemical resistance is one of the main reasons it is chosen. According to industry reports, more than 80% of food manufacturers prioritize material safety. PVDF meets FDA standards, ensuring it is safe for food contact. This feature is crucial in preventing contamination. In addition, it can withstand high temperatures up to 150°C. This heat resistance is beneficial for processes like pasteurization.

Moreover, PVDF tubing is highly flexible and durable. It maintains its shape under pressure, minimizing the risk of leaks. The tubing can handle aggressive environments where other materials might fail. A report by a leading materials scientist indicates that PVDF's lifespan can exceed 20 years in some applications. However, users must still monitor it for any signs of wear. While PVDF is robust, it may not be suitable for every application. Understanding specific needs is essential.

Additionally, the ease of installation of PVDF tubing cannot be overlooked. Its lightweight nature is advantageous for reducing shipping costs. However, improper handling can lead to installation issues. Proper training for technicians is recommended to avoid errors. Ensuring that all staff understands the characteristics of PVDF can lead to better outcomes. Despite its benefits, ongoing evaluation of the application environment is necessary. This ensures that the chosen material remains optimal over time.

Environmental Benefits of Using PVDF Tubing in Sustainable Practices

PVDF (polyvinylidene fluoride) tubing offers significant environmental benefits, making it a key choice in sustainable practices. Its production process has a lower environmental impact compared to other plastics. According to the American Chemistry Council, PVDF exhibits a reduced carbon footprint due to its durability and long lifespan. This reduces the need for frequent replacements.

PVDF is highly resistant to chemicals and UV light, which decreases degradation over time. A study published in the Journal of Applied Polymer Science highlighted its excellent performance in harsh environments. This resilience means fewer materials end up in landfills. In fact, by choosing PVDF, industries can decrease waste generation significantly.

Moreover, PVDF tubing can be recycled. The European Plastic Converters association reported an increase in recycling rates for fluoropolymers, promoting a circular economy. However, challenges remain. Education on proper recycling methods is still needed. Awareness and infrastructure must improve to maximize the benefits of PVDF. Overall, the material presents a sustainable solution yet requires further commitment to recycling practices.

Related Posts

-

Unlocking the Benefits of PVDF Tubing: Why It’s the Future of Industrial Solutions

-

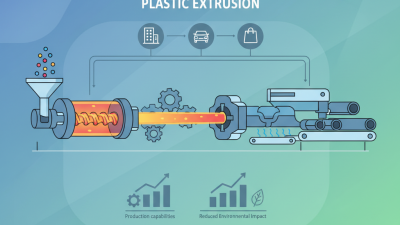

Top 10 Best Plastic Extruders for High Quality Production?

-

10 Essential Tips for Optimizing Plastic Extrusion Profiles and Enhancing Production Efficiency

-

Top 10 Benefits of Using Clear Acrylic Tubes: Why This Material Dominates the Market in 2023

-

Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production

-

What is a Plastic Extruder and How Does it Work in Manufacturing Processes