2026 Guide to PVC Extrusion Profiles: Applications, Benefits, and Types

In the ever-evolving world of manufacturing, "PVC extrusion profiles" stand out as a versatile solution. According to industry expert, John Smith, "PVC extrusion profiles are redefining how we approach design and functionality." This statement captures the essence of their impact.

Applications of PVC extrusion profiles span various sectors. From construction to automotive, their adaptability is unquestionable. They are widely used for windows, doors, and even furniture. The benefits are tangible—durability, cost-effectiveness, and low maintenance. However, there are challenges to consider. Not all profiles meet the required standards.

Understanding the different types of PVC extrusion profiles is crucial. Each type offers unique advantages for specific applications. The market is growing, but innovation must keep pace with demand. It's a reminder that while PVC profiles are beneficial, they must also evolve to maximize potential.

Overview of PVC Extrusion Profiles and Their Core Applications

PVC extrusion profiles are gaining popularity across various industries. They are widely used in construction, automotive, and electrical applications. According to a recent market analysis, the global PVC extrusion market is projected to grow significantly, reaching approximately $40 billion by 2026. This growth is due to their durability, flexibility, and cost-effectiveness.

In construction, PVC profiles serve multiple purposes. They are commonly used for window frames, door frames, and roofing. These profiles are lightweight yet strong, providing excellent insulation properties. The advantages of using PVC over traditional materials include resistance to moisture and termites. However, there are concerns regarding environmental impacts and recyclability, which some companies are beginning to address by developing more sustainable options.

Automotive applications are also expanding, utilizing PVC profiles in interior fittings and seals. They provide design flexibility and help reduce vehicle weight, which can enhance fuel efficiency. Despite their benefits, there are challenges in meeting stringent automotive standards. Continuous improvement and innovation in PVC extrusion techniques are vital for overcoming these obstacles as the market evolves.

2026 PVC Extrusion Profiles: Applications and Benefits

Benefits of Using PVC Extrusion Profiles in Various Industries

PVC extrusion profiles are widely used in many industries due to their numerous benefits. They offer excellent durability and resistance to environmental factors. For example, these profiles can withstand moisture, chemicals, and UV radiation. This makes them ideal for outdoor applications like fencing and window frames. The lightweight nature of PVC also simplifies transportation and installation, saving both time and costs.

In the construction sector, PVC profiles provide versatile design options. They can be easily customized to fit various architectural styles. Their aesthetic appeal is a strong point, yet some may feel they lack the warmth of wood. Additionally, oil and gas industries utilize PVC profiles for containment and piping systems. However, concerns over their environmental impact are rising. The challenge lies in balancing performance with sustainability.

Overall, while PVC extrusion profiles are effective in many applications, it's crucial to continually assess their long-term implications. Striving for better recycling options and reduced resource consumption could enhance their standing. This ongoing reflection can lead to innovation and improved practices across industries.

Different Types of PVC Extrusion Profiles and Their Characteristics

PVC extrusion profiles come in various types, each with distinct characteristics. These profiles serve multiple applications in construction, automotive, and furniture industries. Common types include rigid, flexible, and co-extruded profiles. Rigid PVC profiles are sturdy and weather-resistant. They are often used in window frames and doors. Flexible profiles, on the other hand, offer versatility. They are commonly found in electrical conduits and plumbing systems.

When selecting a profile type, consider its application. Each type has unique benefits. Rigid profiles excel in durability, making them ideal for structural applications. Flexible profiles provide excellent adaptability for intricate designs. Co-extruded profiles combine properties. They feature a tough outer layer with a softer inner core, enhancing performance.

Tips: Always assess your project's specific needs before choosing a profile. Understand the environment where it will be used. Be mindful of potential installation challenges. Profiles that seem perfect might require more effort during application than expected. A careful evaluation can save time and resources later on.

Key Considerations in the Design and Production of PVC Profiles

When designing PVC profiles, several key considerations come into play. A thorough understanding of material properties is essential. PVC is versatile, but its characteristics can vary based on formulations. Choosing the right type will influence the final product's durability and performance. Tips: Always test different formulations before settling on one. Small changes in additives can lead to significant performance variations.

Production methods also matter. Vacuum forming, extrusion, and injection molding are common techniques. Each method has its pros and cons. For example, extrusion allows for continuous shapes but may limit intricate designs. Meanwhile, injection molding can create detailed profiles but often requires more initial investment. Tips: Evaluate your design complexity against production costs. A simple design might save you money and time in the long run.

Finally, consider the end application of the PVC profiles. Different industries have unique requirements. Profiles used in construction must withstand harsh environments. However, those for decorative applications might prioritize aesthetics over strength. Tips: Engage with potential users early in the design phase. Their feedback can save you from costly revisions later.

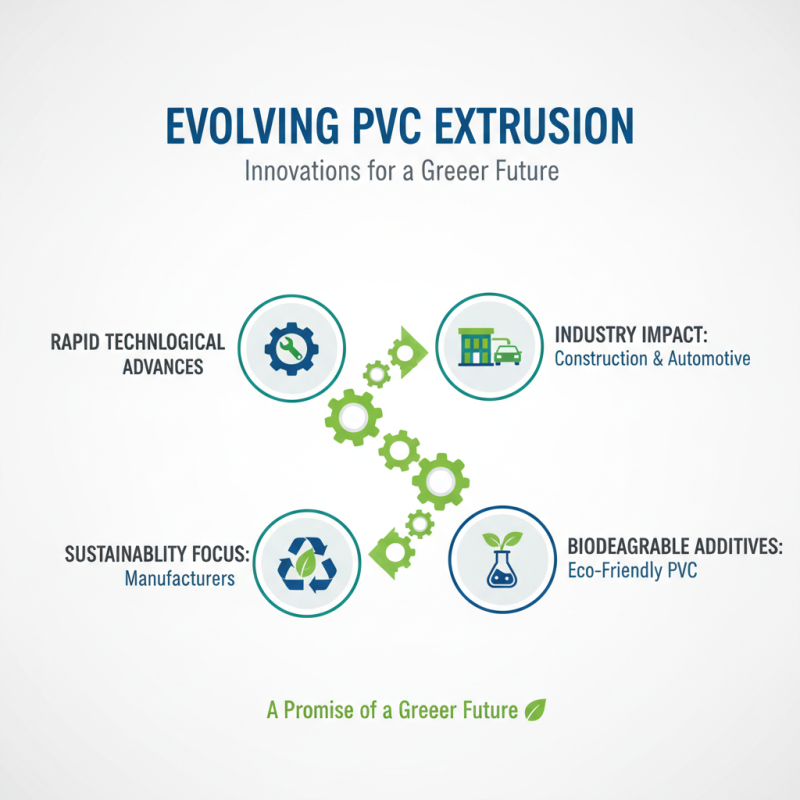

Future Trends and Innovations in PVC Extrusion Technology

The PVC extrusion technology landscape is evolving rapidly. Innovations are emerging, impacting industries like construction and automotive. Manufacturers are focusing on sustainability. Biodegradable additives are being explored. These advances promise a greener future for PVC products.

One notable trend involves integrating smart technology into PVC profiles. Sensors embedded in the materials can monitor structural integrity. This could revolutionize how we approach maintenance. However, these innovations may introduce complexities. There’s still much to figure out regarding costs and implementation.

The shift toward customization is evident as well. Clients increasingly demand tailored solutions. This can strain production processes. Balancing efficiency with personalization presents challenges. The future might be bright, but the road ahead is uncertain. Adaptation is essential for success in this dynamic field.

Related Posts

-

Top 5 Benefits of PVC Extrusions for Modern Construction and Design

-

2025 Top 5 PVC Extrusion Profiles for Durable and Versatile Applications

-

How to Choose the Right PVC Extrusion Profiles for Your Project

-

2025 Top Trends in Flexible Plastic Tubing: Innovations and Applications

-

Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production

-

Exploring the Versatility of Polycarbonate Tubes: Innovations in Design and Application