2025 Top Trends in Flexible Plastic Tubing: Innovations and Applications

The flexible plastic tubing industry has experienced remarkable growth and innovation, positioning itself as a critical component across various sectors, including medical, automotive, and food and beverage industries. According to a recent market analysis by Grand View Research, the global flexible plastic tubing market is projected to reach USD 9.4 billion by 2025, growing at a CAGR of 6.8% from 2019 to 2025. This surge is driven by the increasing demand for versatile, lightweight, and durable tubing solutions that offer superior performance and adaptability in diverse applications.

As highlighted by industry expert Dr. Emily Carter, a leading authority in polymer technology, "The future of flexible plastic tubing lies in its ability to innovate and meet the evolving needs of various industries." Innovations in materials and manufacturing processes are paving the way for new applications, enhancing the functionality and sustainability of flexible plastic tubing products. With advancements in biocompatible materials and recycling technologies, the sector is focusing on reducing environmental impacts while maintaining high performance standards.

In conclusion, as we delve into the top trends shaping the flexible plastic tubing landscape in 2025, it becomes evident that ongoing research and development, coupled with a keen focus on sustainability, will be pivotal in driving the industry's future. The next wave of innovations not only promises to bolster efficiency but also to address pressing environmental challenges, making flexible plastic tubing integral to a greener future.

Current Market Overview of Flexible Plastic Tubing in 2025

The flexible plastic tubing market in 2025 is poised for significant growth, driven by advancements in material technology and increasing demand across various industries, including healthcare, automotive, and food processing. According to a recent industry report, the global flexible plastic tubing market is expected to reach approximately $9 billion by 2025, growing at a compound annual growth rate (CAGR) of over 6% from 2020. This surge is largely attributed to the rising adoption of flexible tubing for applications requiring lightweight, corrosion-resistant, and easy-to-install solutions.

In the healthcare sector, innovations in biocompatible materials are enabling the development of flexible plastic tubing that meets stringent safety standards for medical use. Reports show that flexible plastic tubing is increasingly utilized in medical device manufacturing, particularly in IV administration and catheter applications, where reliability and patient comfort are paramount. Furthermore, the food and beverage industry is seeing a shift towards flexible tubing solutions that enhance sanitation and reduce contamination risks, aligning with global safety standards and consumer health trends. The market dynamics reflect a growing emphasis on sustainability as manufacturers explore biodegradable and recyclable materials for flexible tubing, catering to the increasing consumer preference for eco-friendly products.

Key Innovations Driving the Flexible Plastic Tubing Industry Forward

The flexible plastic tubing industry is undergoing a significant transformation, driven by key innovations that enhance performance and sustainability. Recent market analysis indicates that the flexible plastic tubing market is projected to reach approximately $7.5 billion by 2025, with compounded annual growth rates of over 7% due to the increasing demand across various sectors such as healthcare, food and beverage, and automotive. One of the notable innovations is the development of bio-based and biodegradable materials, which cater to the rising consumer preference for environmentally friendly products. According to the recent report by Smithers, the adoption of such materials is expected to rise by nearly 30% over the next few years.

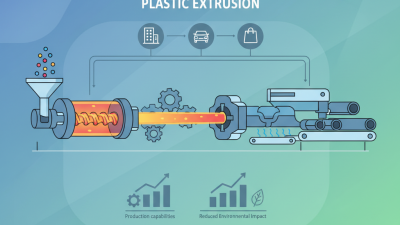

Moreover, advancements in manufacturing technologies, including extrusion innovations and enhanced polymer formulations, are boosting the durability and adaptability of flexible plastic tubing. High-performance tubing solutions are being engineered to withstand extreme temperatures and pressures, ensuring safety and reliability in critical applications. A study by Freedonia Group highlights the growing trend of smart tubing, which incorporates sensors to monitor flow rates and conditions, presenting significant opportunities for industries focused on efficiency and real-time data collection.

Tips: When selecting flexible plastic tubing for specific applications, consider factors such as temperature resistance, chemical compatibility, and pressure ratings to ensure you choose the right solution for your needs. Additionally, staying informed about the latest material developments and innovations can help in making more sustainable choices that contribute positively to environmental goals.

Sustainability Trends: Eco-Friendly Materials in Plastic Tubing

The flexible plastic tubing industry is witnessing a significant shift towards sustainability, reflecting the heightened awareness of environmental issues among manufacturers and consumers alike. According to a recent market analysis by Grand View Research, the global eco-friendly plastic tubing market is projected to reach $3.2 billion by 2025, with a compound annual growth rate (CAGR) of 5.9%. This growth is driven by increasing demand for sustainable materials that minimize environmental impact while maintaining the performance characteristics needed for various applications.

One key innovation is the development of biodegradable and compostable plastics that offer an alternative to traditional petroleum-based materials. For instance, bioplastics made from renewable resources such as cornstarch and sugarcane are gaining traction in the industry. A report from the Biodegradable Plastics Institute indicates that consumer preference is shifting towards these eco-friendly options, with KPMG reporting that 48% of global consumers are willing to pay a premium for products that contribute to sustainable development. This trend is prompting manufacturers to invest in research and development to create high-performance flexible tubing that does not compromise on durability or safety while being environmentally responsible.

Furthermore, recycling initiatives are becoming increasingly important as the industry adapts to a circular economy model. The Plastic Industry Association highlights that the recycling rate for flexible plastic products is currently around 14%, but with enhanced recycling technologies and initiatives, there is potential for this figure to increase significantly. By adopting closed-loop systems and utilizing recycled materials in new products, manufacturers are not only reducing waste but also decreasing overall production costs, making eco-friendly tubing options more viable. As these sustainability trends continue to unfold, the flexible plastic tubing sector is poised for a transformative evolution, prioritizing both ecological impact and innovation.

2025 Top Trends in Flexible Plastic Tubing: Innovations and Applications

| Trend | Description | Sustainability Impact | Application Areas |

|---|---|---|---|

| Biodegradable Tubing | Development of tubing materials that decompose naturally over time. | Reduces plastic waste in landfills and oceans. | Medical, agriculture, and packaging industries. |

| Recycled Materials | Use of post-consumer recycled plastics in tubing manufacturing. | Conserves resources and reduces energy consumption. | Construction, automotive, and consumer goods. |

| Smart Tubing | Incorporation of sensors for real-time data monitoring. | Improves efficiency and reduces waste through better resource management. | Healthcare, food & beverage, and chemical processing. |

| Thermal Regulation | Tubing that maintains temperature control for sensitive materials. | Enhances sustainability in temperature-sensitive supply chains. | Pharmaceuticals, food logistics, and chemical transport. |

| Lightweight Designs | Creation of thinner, lighter tubing that maintains strength. | Reduces material use and energy consumption during transportation. | Aerospace, automotive, and flexible manufacturing. |

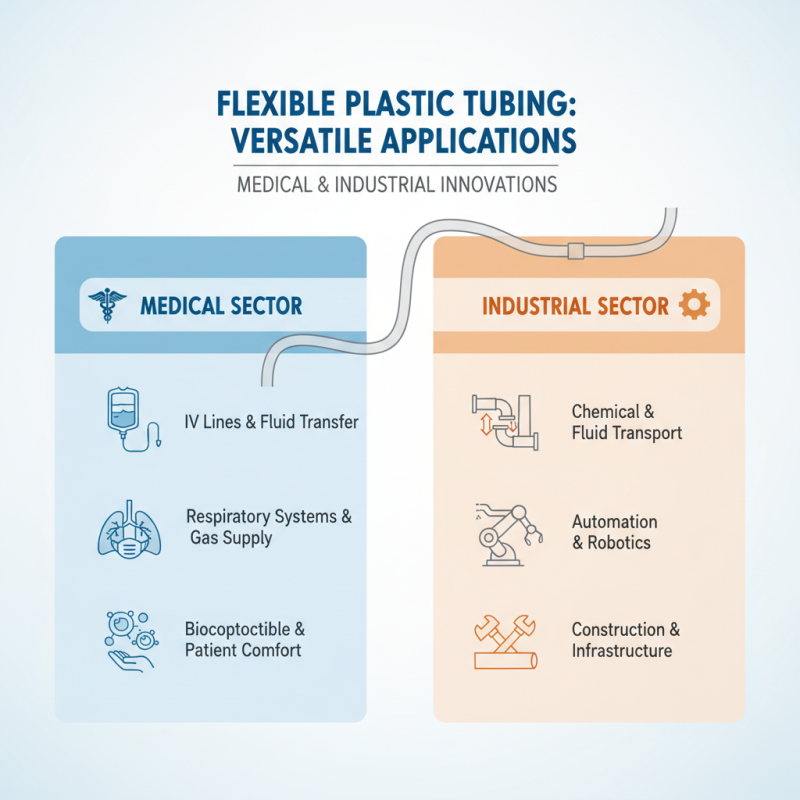

Applications of Flexible Plastic Tubing in Medical and Industrial Sectors

Flexible plastic tubing has become integral in both the medical and industrial sectors, offering versatile solutions for various applications. In the medical field, flexible plastic tubing is crucial for patient care, facilitating the transfer of fluids and gases in devices such as IV lines and respiratory systems. Its lightweight and flexible nature allows for easy maneuverability, which is vital in emergency situations where speed is critical. Moreover, advancements in materials technology have led to the development of biocompatible tubing options that enhance patient safety and comfort.

In industrial applications, flexible plastic tubing is widely used for conveying liquids and gases in systems that demand high durability and resistance to chemical corrosion. Industries such as manufacturing and food processing rely on these tubes to ensure efficient operation and maintain cleanliness. The adaptability of flexible tubing also makes it suitable for high-pressure applications, ensuring optimal performance under varying conditions.

**Tips:** When selecting flexible plastic tubing for medical applications, consider biocompatibility and sterilization methods to ensure safety. For industrial use, evaluate the tubing's chemical resistance and pressure ratings to match your specific operational requirements. Regular inspections can also help maintain integrity and prevent unexpected failures, ultimately improving efficiency.

Future Challenges and Opportunities in Flexible Plastic Tubing Market

The flexible plastic tubing market is poised for significant evolution as we approach 2025, driven by both innovations and emerging challenges. One of the primary opportunities lies in the sustainability movement. As environmental concerns become more prevalent, manufacturers are increasingly focusing on developing eco-friendly materials and production processes. Innovations in biodegradable plastics and recycling technologies stand to reshape the market, offering promising alternatives that align with global sustainability goals. Companies that can successfully implement these solutions will not only meet regulatory demands but also cater to an increasingly conscious consumer base.

However, the industry faces several challenges that must be addressed to fully capitalize on these opportunities. One of the most pressing issues is the need for enhanced performance characteristics in flexible plastic tubing, such as durability and resistance to temperature fluctuations. Additionally, the cost of transitioning to more sustainable materials can be high, deterring some manufacturers from making the switch. As the market evolves, businesses will need to navigate these obstacles while investing in research and development to innovate without compromising on functionality or cost-effectiveness. Flexibility, resilience, and sustainability will be key pillars for success in this dynamic market landscape.

Related Posts

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions

-

10 Best Uses for Clear Plastic Tubes in Your Projects and Crafts

-

How to Choose the Right Plastic Hinges for Your Project Needs

-

Top Uses for Clear Acrylic Pipe in 2025 and Its Benefits for Your Projects

-

What is a Plastic Extruder and How Does it Work in Manufacturing Processes

-

Top Uses for Clear Plastic Tubes in 2025 and Innovative Ideas You Need to Know